[

Well, let me tell you about this cold rolled stainless steel coil. You see, it’s one of them fancy metal things that folks use in all sorts of stuff. Strong and light, just like a good bird’s feather but can’t break easy. They take hot rolled steel coils, which is like the rough version, and then they run it through some heavy machines to make it cold and shiny.

Now, what’s this cold rolling, you ask? It’s when they press and draw the steel at room temperature. So, they take that hot stuff, let it cool down a bit, and then keep rolling it. This way, the steel gets all the right shapes and smooth finishes, just like how you’d want your dough to be when you’re making pie crust!

Why is it special, you wonder? Well, this here cold rolled stainless steel is used in many important places, like airplanes, hospitals, and cars. It’s tough enough to last but light enough to not weigh a ton. You can even find it in those fancy machines that doctors use to help people.

- Used in aerospace industry

- Popular in medical equipment

- Important for automotive parts

- Also seen in nuclear plants

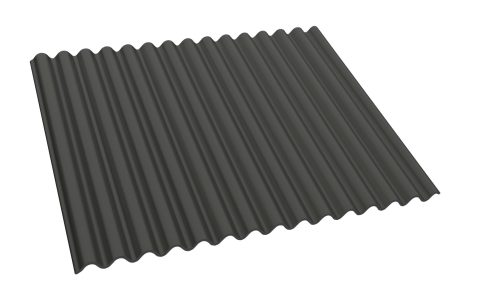

So, when they’re making this cold rolled steel, they really know what they’re doing. After it gets all pressed and drawn, the steel comes out with better shapes and sizes. It’s like when you take a block of clay and mold it into something pretty! This cold rolled stuff gets closer to what folks need than that hot rolled steel ever could.

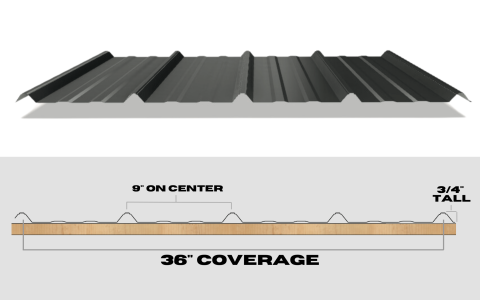

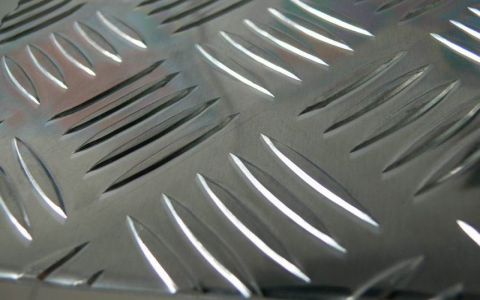

Now, you might not think it, but this steel can be used in all sorts of finishes. You got shiny ones, dull ones, and all kinds of textures. It’s like choosing your favorite fabric when making a quilt. Everyone has their own pick, and it all depends on what they’re making.

One thing to remember is that when you work with this steel, it can be a bit different because it can get magnetic. That’s because when they cool it down slowly, it changes a bit inside. It’s like how some folks can get grumpy if you wake them up too fast!

How do they make it? Well, the process starts with hot rolled steel. They roll it out while it’s hot, and then let it cool. Once cooled, it goes back to the machines, where they roll it again at room temperature. This makes it thinner and easier to work with. It’s like rolling out dough for a pie but doing it just right so it fits the pan perfectly.

And you know, once this steel is all made, it can be shipped out all over the place. Factories and companies need this stuff to make all sorts of products. It’s a big deal in manufacturing, I tell ya!

People often ask why they’d use cold rolled over hot rolled. Well, the answer is simple. Cold rolled steel has tighter tolerances, meaning it’s more precise. It’s like measuring out ingredients when you bake; you want them to be just right for the best outcome.

Lastly, if you ever see this cold rolled stainless steel coil, just remember how much work goes into making it. It’s not just metal; it’s a whole process of getting it from rough to smooth, ready for all the important jobs it has to do in the world.

]

Tags:[Cold Rolled Stainless Steel, Stainless Steel Coil, Metal Products, Manufacturing]