Alright, let’s talk about this 14ga steel thickness thing. I ain’t no fancy engineer, but I know a thing or two about metal, you see. Been around it long enough.

So, this 14 gauge steel, what’s it all about? Well, they got these numbers, see? The lower the number, the thicker the steel. Sounds backwards, I know, but that’s how them city folks do things. This 14 gauge, it’s about…lemme see… they say it’s like 0.0747 inches thick. Or, if you’re like me and like things simple, it’s about 1.9 millimeters. That ain’t too thick, and it ain’t too thin neither. Just right, for some things.

Now, why does this thickness matter? Well, it’s all about strength, you see. The thicker the steel, the stronger it is. But, and this is a big but, thicker steel ain’t always better. It’s harder to bend, see? It’s like trying to bend a thick ol’ tree branch versus a twig. The twig bends easy, the branch, not so much. So, if you need something strong but still gotta bend it, 14 gauge might be just the ticket.

- Thicker steel = stronger but harder to bend

- Thinner steel = easier to bend but not as strong

- 14 gauge = kinda in the middle, good for lots of things

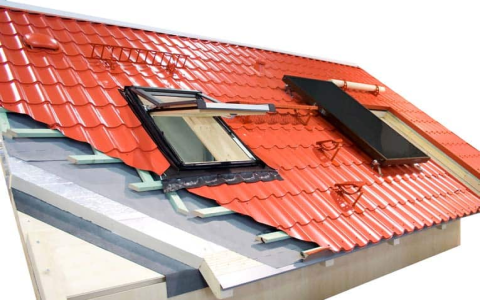

They use this 14 gauge steel for all sorts of stuff. You might see it in roofs, you know, them metal roofs they got now. Keeps the rain out, keeps the house warm. Good stuff. They also use it in cars, I hear. Not the whole car, mind you, but parts of it. Gotta be strong enough to keep you safe, but not so heavy it can’t move.

And then there’s all them other things, like… what do you call it… metal fabrication? Yeah, that’s it. Making stuff outta metal. You gotta pick the right thickness for the job, see? Can’t just use any old piece of steel. Gotta think about what it’s for, how strong it needs to be, how much it needs to bend. It’s like baking a cake. You gotta use the right amount of flour, the right amount of sugar, or it ain’t gonna turn out right. Same with steel.

Now, they got these fancy charts and stuff, tells you all about the different gauges and thicknesses. And they talk about different kinds of metal too, not just steel. Aluminum, copper, all that stuff. Each one’s got its own thing going on, you know? But we’re talking about 14 gauge steel here, so let’s stick to that.

So, if you’re building something, and you need some steel, you gotta think about this thickness. Do you need something strong and sturdy? Or do you need something that’s easy to work with? 14 gauge might be the answer, it might not. It all depends on what you’re doing.

This choosing the right metal thickness, they say it’s real important. Whether you’re building houses or making car parts or just doing some artsy metal stuff, the thickness makes a difference. It’s not something you can just ignore, you know?

And let me tell you, figuring out this metal stuff ain’t easy. But it’s important. You don’t want your roof falling in, or your car falling apart, just because you picked the wrong thickness of steel. So, do your homework, ask questions, and make sure you get it right.

So there you have it. A little bit about 14 gauge steel thickness. It ain’t rocket science, but it ain’t nothin’ neither. Just remember, thicker ain’t always better, and thinner ain’t always worse. It’s all about finding the right fit for the job. And that, my friend, that takes a little bit of common sense and a whole lot of knowing what you’re doing.

And that’s about all I got to say on that. You get the gist of it, right? Good.

Tags: [14 gauge steel, steel thickness, metal gauge, sheet metal, metal fabrication, steel strength, metal properties]