Well, now let me tell ya, this “slit coil” thing, it’s just a fancy way of saying they’re taking a big ol’ roll of metal and cutting it down to smaller bits. You got this giant coil, and instead of using the whole chunk, they go and slice it up into skinny strips. It’s kinda like, ya know, taking a big loaf of bread and cutting it up so’s it’s easier to chew. Real handy, right?

What’s This Coil Slitting Really About?

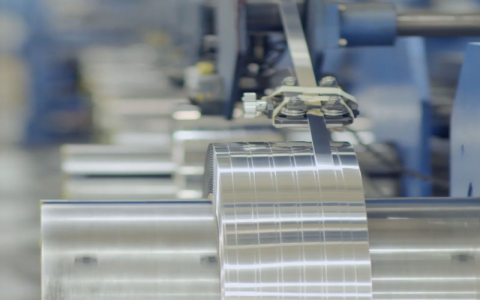

Alright, so here’s what’s goin’ on. They call it “coil slitting,” and it’s just a part of the metalwork biz. You got a big coil, they call it a “master coil,” and it’s wide, way too wide for most stuff. So, they gotta cut it down. They use these round blade things—rotary knives, they call ‘em. And they cut that big coil into smaller coils, usually called “mults.” Those “mults” are just them skinny rolls, easier to handle and use for other projects.

Why Bother Slitting Coils?

Now, ya might be wonderin’, why go through all that trouble? Well, turns out, there’s a whole bunch of reasons:

- Easy to Handle – Big coils are heavy and awkward. But once they’re cut into these skinny mults, they’re way easier to move around.

- Perfect Fit for Different Jobs – Not every project needs a big ol’ chunk of metal. Slitting lets folks get the size they need without wastin’ material.

- Saves Money – Smaller pieces can mean less waste. They can just use what they need, and not end up with big scraps everywhere.

What Do They Use Slit Coils For?

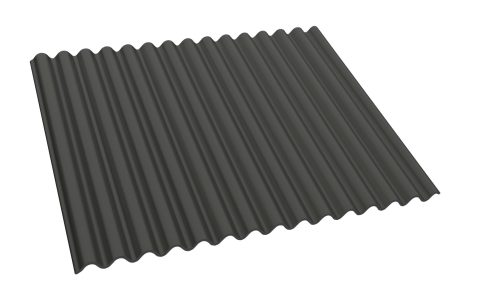

These slit coils? Oh, they’re everywhere! Factories and all sorts of industries use ‘em. Say you’re makin’ some car parts or, heck, even a fridge—those need thin pieces of metal cut just right. Stainless steel, carbon steel, aluminum—just about any metal you think of can be slit, so they got a use for all sorts of jobs. Buildings, machines, ya name it.

Precision in Coil Slitting

Here’s the other thing—ya gotta be real careful with these cuts. Folks in the slitting biz talk about “precision” all the time. That’s ‘cause if the cuts ain’t perfect, you got metal edges all rough or uneven, which could mess up the whole project. So, these companies invest in good equipment. Some of ‘em got machines that can cut down to tiny measurements, even under .002 inches. Ain’t that somethin’?

Materials for Coil Slitting

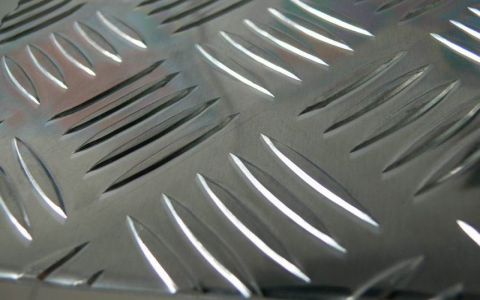

Now, let’s talk about what kinda metals they’re usually workin’ with. Stainless steel, that’s a big one, ‘specially for stuff like kitchen appliances. But they also work with aluminum, carbon steel, and copper, dependin’ on what the job calls for. Each metal’s got its own way of bein’ handled. Some folks even order special edges, like with a “safe edge,” to avoid any nasty cuts when folks are handlin’ it later.

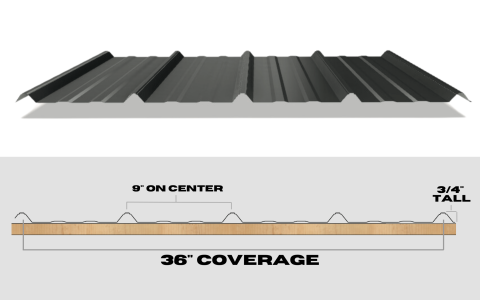

Colors, Sizes, and Options Galore

Ya wouldn’t believe it, but you can even order slit coils in different colors! Yep, for buildin’ projects, they got ‘em in colors to match walls, roofs, and all that. And then there’s all kinds of sizes, gauges, widths. Some folks want thicker coils, some want real thin. Whatever size they need, there’s likely a coil ready for ‘em.

So How’s It Done? A Peek at the Process

First up, they take that big ol’ master coil and load it on a machine called a slitter. Then, these blades—look like big round knives—come down and start cuttin’. Some machines even got thirty or more of these blades, all cuttin’ at once. They spin ‘round and round, slicin’ up that big coil into nice little strips. The strips get rolled up again into new coils, ready to ship off.

Slit Coils in Real Life

Take a look around your house or the street—chances are you’ll spot stuff that’s got slit coil metal in it. Cars, home appliances, even the siding on houses, all of ‘em might have some metal that started out in a big coil and got slit down to size. There’s companies out there with big warehouses full of these coils, all set to be cut, packed, and shipped off for the next big project.

Wrap It All Up

So there ya have it—slit coils! It’s just another way to take a big ol’ hunk of metal and make it fit what folks actually need. Instead of wastin’ metal or workin’ with more than they can handle, companies slice it down to size. Saves money, makes it easier to use, and gets the job done. Ain’t that somethin’?

Tags:[slit coil, coil slitting, metal slitting, manufacturing, precision cutting, metal industry, stainless steel coil]