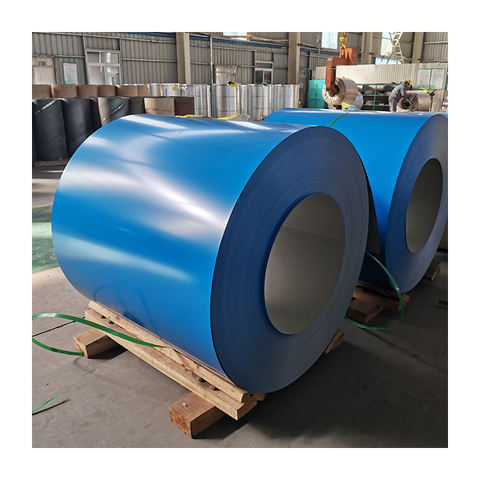

Blue PPGI: Stylish, Durable, and Versatile Steel Coils for a Range of Applications

Blue PPGI (Pre-painted Galvanized Iron) coils have emerged as a popular material choice for industries seeking a balance of aesthetic appeal, durability, and functionality. This distinctive steel product, coated in vibrant shades of blue, has applications across sectors including construction, appliances, and automotive industries, where it brings both practicality and a visually appealing finish. In this article, we’ll explore what blue PPGI is, its benefits, various uses, and the key reasons it’s a preferred material for numerous commercial and industrial projects.

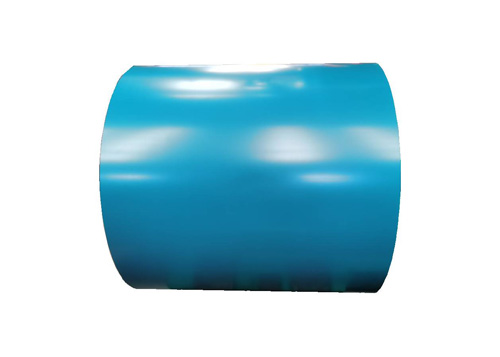

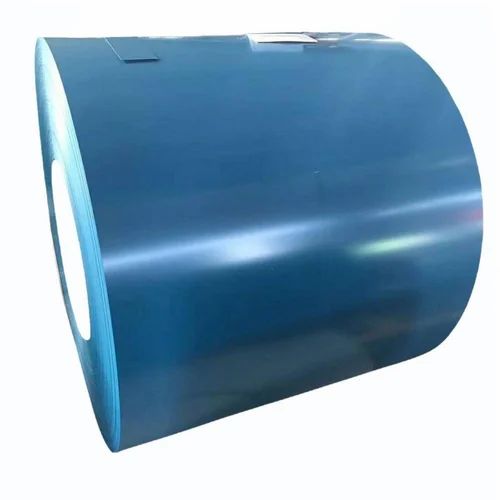

What is Blue PPGI?

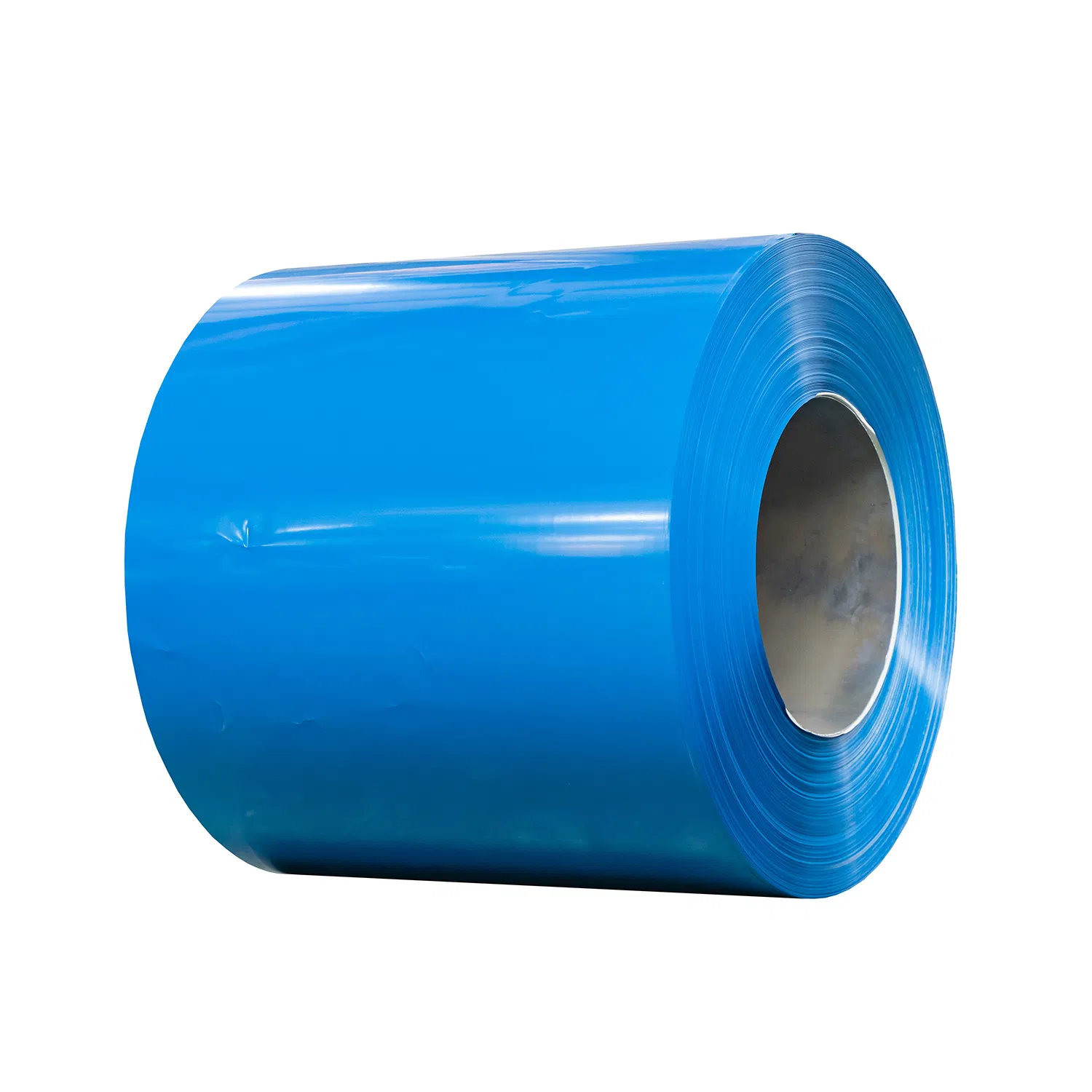

Blue PPGI is a type of pre-painted galvanized iron coil, created by coating galvanized steel with layers of primer, paint, and often additional finishes to achieve a protective and decorative surface. This high-quality, durable coil is coated in blue, which not only gives it a visually attractive appearance but also enhances its resistance to weather, corrosion, and mechanical wear. The color coating is applied through a continuous coil coating process, which ensures consistent quality and uniform color, producing a ready-to-use material that combines the advantages of both steel and protective coatings.

Advantages of Blue PPGI

1. High Durability and Corrosion Resistance

One of the primary benefits of blue PPGI is its high corrosion resistance. The galvanized layer on the steel coil provides a protective barrier against moisture, oxidation, and rust, while the additional layers of primer and color coating reinforce its durability. This makes blue PPGI suitable for both indoor and outdoor applications, where it will remain resistant to the elements and maintain its vibrant color over time.

2. Aesthetic Appeal

The eye-catching blue color of PPGI coils brings a unique aesthetic dimension to any project. Available in a range of blue shades, from deep navy to lighter sky blue, these coils add a pop of color that can enhance the visual appeal of buildings, appliances, and other products. This color versatility allows designers and manufacturers to create products that stand out or blend in with the surrounding environment, according to project requirements.

3. Easy to Work With

Blue PPGI is easy to process, cut, and shape, which makes it versatile for various manufacturing and construction applications. Its flexibility and adaptability allow for custom cuts and bends, making it ideal for projects that require unique shapes or sizes. It can also be easily assembled, reducing labor costs and speeding up installation processes.

4. Low Maintenance

Compared to traditional steel, blue PPGI coils are low maintenance. The protective layers shield the material from fading, scratches, and peeling, eliminating the need for regular painting or polishing. This low-maintenance nature makes it a cost-effective choice, especially for large-scale projects where long-term durability is a priority.

5. Cost-Effective Solution

While the initial investment in PPGI might be slightly higher than uncoated steel, its durability and low maintenance make it a cost-effective choice in the long run. The high-quality coating eliminates the need for additional treatments or repairs, reducing both labor and material costs over the lifespan of a project.

Applications of Blue PPGI

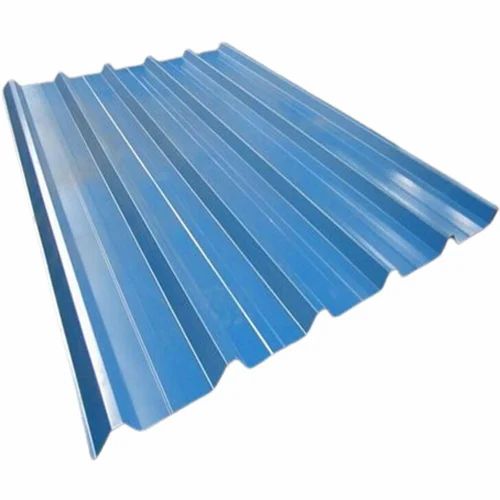

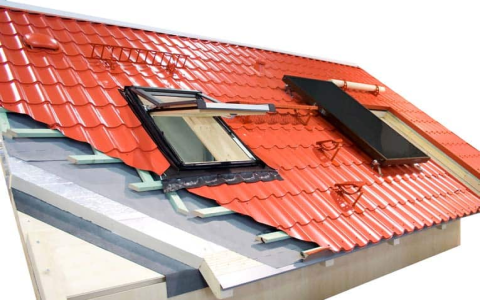

1. Construction and Building Exteriors

Blue PPGI is widely used in the construction industry, particularly for roofing, cladding, and building facades. Its corrosion resistance and aesthetic appeal make it an excellent material for roofs, especially in coastal or humid environments where traditional materials may not hold up. The blue color adds a modern, clean look to structures, making it a preferred choice for commercial buildings, industrial warehouses, and residential properties.

2. Interior Decoration

For interior applications, blue PPGI brings a refreshing color to walls, partitions, and ceiling panels. Its durability and resistance to scratches make it ideal for high-traffic areas, and its blue color can be used to create visually interesting spaces that feel both calming and contemporary. The versatility of blue PPGI also allows it to be applied in a variety of finishes, from matte to glossy, enhancing its aesthetic flexibility for different interior styles.

3. Home Appliances

Many home appliance manufacturers use blue PPGI to add a unique look to appliances like refrigerators, washing machines, and microwaves. The durability of blue PPGI helps protect appliances from everyday wear and tear, while the vibrant color adds a modern and sophisticated aesthetic to kitchen and laundry spaces. This use in appliances showcases the material’s ability to combine form and function, providing both durability and a design-forward look.

4. Automotive Industry

Blue PPGI is also used in the automotive sector, primarily for vehicle parts that require corrosion resistance and durability. From truck trailers to recreational vehicles, blue PPGI is applied to components that are exposed to weather and environmental factors. The material’s corrosion resistance extends the lifespan of these parts, and the blue color enhances the vehicle’s visual appeal, making it a popular choice for customization and design.

5. Agricultural and Industrial Equipment

In agriculture, blue PPGI is commonly used for machinery covers, storage containers, and equipment that are frequently exposed to moisture, chemicals, and rough handling. Its resistance to chemicals, weather, and physical damage makes it ideal for protecting equipment used in demanding agricultural environments. Industrial equipment and storage facilities also benefit from blue PPGI’s robustness, as it shields materials from rust and provides a durable, low-maintenance solution.

Key Considerations When Choosing Blue PPGI

1. Color Consistency and Quality

Not all PPGI products are the same. When choosing blue PPGI, it’s essential to select high-quality products from reputable suppliers to ensure color consistency, coating adhesion, and long-lasting performance. Inconsistent quality can lead to fading, peeling, or corrosion, especially in outdoor applications.

2. Thickness and Coating Layer

The thickness of both the steel and coating layers should be chosen based on the intended application. Thicker steel provides added durability, while the coating’s thickness determines its resistance to environmental factors. Outdoor applications, for instance, will benefit from thicker coatings that provide added protection against UV rays, moisture, and other environmental challenges.

3. Environmental Factors

When selecting blue PPGI for outdoor projects, consider the climate and weather conditions the material will be exposed to. Coatings with high UV resistance are recommended for areas with intense sunlight, while coastal or humid regions require PPGI with excellent corrosion resistance to avoid rust and oxidation over time.

4. Customization Options

Blue PPGI comes in various shades, patterns, and finishes, allowing designers to create custom looks that suit specific projects. Consult with manufacturers to explore customization options, including texture, color intensity, and gloss level, to ensure the product aligns with the project’s aesthetic and functional requirements.

Why Blue PPGI is a Smart Choice for Modern Projects

Blue PPGI offers a unique combination of durability, aesthetic appeal, and versatility, making it an ideal material for modern construction, manufacturing, and design applications. Its range of blue shades allows for customization and design flexibility, while its strength and resistance to environmental factors make it a practical choice for demanding applications. From enhancing a building’s exterior to adding a touch of style to household appliances, blue PPGI proves that functionality and beauty can go hand in hand.

Moreover, as industries and consumers alike move towards sustainable choices, blue PPGI aligns with eco-friendly objectives. Using pre-painted steel reduces the need for additional painting or finishing, minimizing waste and environmental impact. The material’s long lifespan and recyclability contribute to sustainable project goals, making blue PPGI a smart and responsible choice.

Conclusion: The Value of Blue PPGI in Design and Industry

As a blend of practicality and design, Blue PPGI is more than just a steel coil; it’s a solution that meets both aesthetic and functional demands. With its range of applications, from building facades to automotive components, it continues to play a vital role in modern industry. Its blue color adds a vibrant touch, while its durability, low maintenance, and corrosion resistance make it an invaluable material for projects that demand both performance and style. Whether you’re an architect, builder, or product designer, blue PPGI offers the durability you need and the aesthetic you desire for a variety of applications.