You know, steel, it’s like that tough iron we all know, but cold rolled coil steel is something a bit different. This kind of steel don’t come out rough and bumpy like them other steels. No, this one goes through a real smooth process that’s called cold rolling, and it’s got some fancy uses too. Let me tell ya a bit about it in simple terms, like folks from the village might understand, alright?

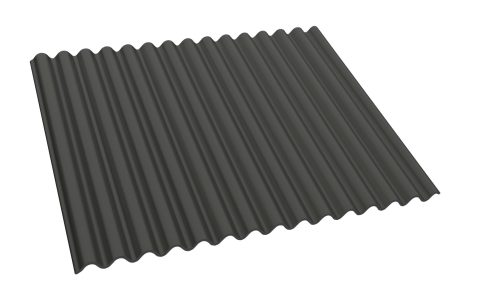

First thing, cold rolled steel, it starts off like any other steel, real hot. They call that hot rolling, where they heat the metal up high till it’s all flexible, then roll it out nice and flat. But here’s where things get interesting. When that hot rolled steel cools down, they run it through the roller machine again at room temperature – no heat this time, so they call it cold rolling. This second time around, it gets real tight and smooth.

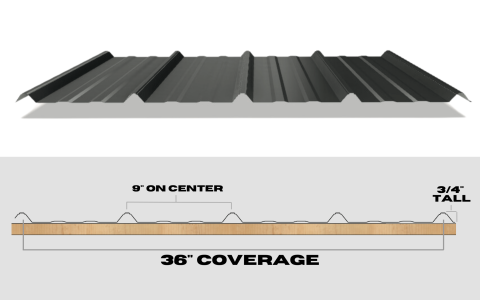

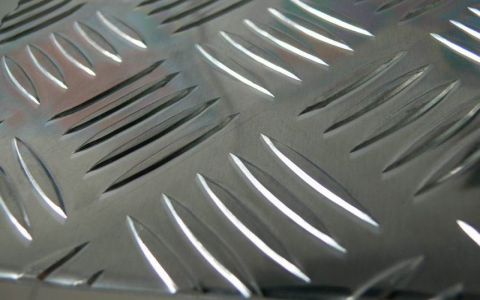

Now, why go through all that trouble? Well, turns out cold rolled coil steel comes out with better edges and a nice finish. No rough spots, no rusty bits hanging off, just clean, smooth steel. And folks say it’s strong too! That cold rolling makes the steel harder ’cause of something called dislocation tangling – I can’t say I know what that is exactly, but just know it makes the steel tougher.

But, you know, even tough stuff can be too tough sometimes. So sometimes they gotta anneal it. Annealing’s like giving the steel a good rest to soften it back up a bit so it’s easier to shape for whatever they’re gonna make outta it. You get that balance, not too soft, not too hard.

So, where do they use this kind of steel, you might wonder? Let me break it down:

- Automotive stuff: Car parts, especially the bits that need to look nice and hold up against wear and tear, they love this steel for that.

- Medical equipment: Now, for the tools and machines in hospitals, you need something clean and precise, right? Cold rolled steel fits that job, no problem.

- Aerospace stuff: Planes, they use this too! They need materials that’re strong but not too heavy, and cold rolled steel gives ’em that.

See, compared to hot rolled steel, cold rolled coil steel’s got less flaws. Hot rolled steel, it’s useful too, but it comes out rough and needs some work to clean up the edges, maybe even some treatments to stop rust and whatnot. But this cold rolled steel skips all that, comes out of the machine real smooth, ready to use for fancy things.

Some big companies, like NIPPON STEEL, they’re makin’ cold rolled steel all day. They handle every bit of the process from raw iron to finished steel, no messing around. They know if they get each step right, the steel’s gonna come out just the way folks need it. And there’s companies like Zeeco Metals too that understand what it takes to get cold rolled steel just perfect for all those important uses.

So next time you hear about cold rolled steel, remember, it ain’t just some slab of metal. It’s a refined, worked-on steel that’s strong and smooth, ready for cars, planes, hospital tools, you name it. That cold rolling – takes some effort, but it sure brings out a steel that’s worth every bit of work they put in.

Tags:[cold rolled steel, cold rolled coil steel, automotive steel, medical steel, aerospace steel, annealing, hot rolled steel]