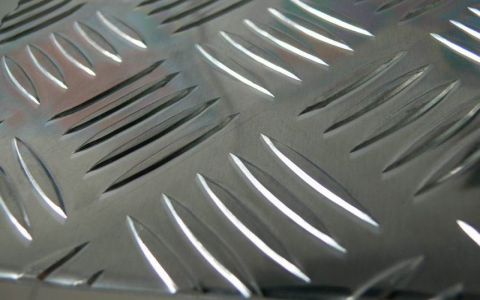

Steel coil processing, to put it simply, is to cut and pull these large iron coils according to people’s needs and make them into different shapes. Now, the steel coil processing on the market is mainly divided into two major categories: hot rolling and cold rolling. Hot rolling means heating the steel to a certain temperature, and it can be pulled and rolled up after softening, but the surface is a bit rough. Cold rolling is different. It does not need to be heated, but rolled directly. The surface of the steel coil is flat and the size is more accurate.

Now, steel coils need to be processed into different shapes and sizes. Here, there are two ways:

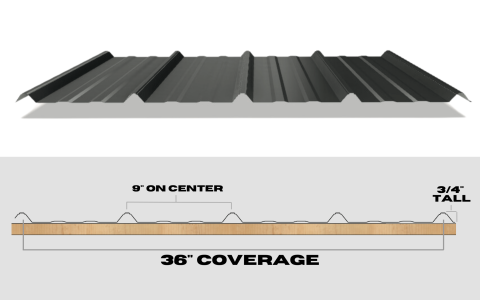

Cut to Length (CTL): Cut the large steel coil into steel plates of fixed size. This process can be used directly in places where a whole steel plate is needed, such as buildings and home appliances.

Cut to Strip (Cut to Width, also called strip processing): Cut the steel coil into narrow strips along the length, and these narrow strips can be rolled up again. This is used in cars, airplanes, and even home appliances where steel strips are used.

Another point is that stress will be generated during cold rolling of steel coils, and annealing is required at this time. What is annealing? Simply put, it is to eliminate stress with high temperature, so that the steel is not so brittle and has better toughness. Therefore, generally cold-rolled steel has to go through this process.

Let’s talk about the benefits of processing. Steel coils can be said to be a versatile material that can be cut, rolled, and pulled. For example, the outer shells of airplanes and ships, as well as thin plates and water tanks in home appliances, can all be used. Moreover, this kind of steel coil processing is also very suitable for those automated equipment. Not only is it efficient, but the quality of the products is also guaranteed, so the cost is naturally lower.

Let’s talk about the equipment for steel coil processing. There are many main tools in it, such as laser cutting machines and automatic sorting machines, which ensure the flexibility and high production capacity of the entire production line. These equipment are not small gadgets. The steel coils are automatically loaded and unloaded throughout the entire production line, and the last processed steel coils are automatically arranged, saving manpower.

To sum up, steel coil processing is to cut large steel coils into different specifications according to demand, and the sliced steel plates and the stripped steel strips are narrow strips. After annealing and automated equipment processing, whether you want large steel plates or narrow steel strips, you can get stable quality finished products. Now, these processed steels can be used in almost any field, not only for industrial needs, but also for home appliances and construction. This steel coil processing is a universal method, saving time and money, and it is very convenient!

Tags:[steel coil processing, hot rolling, cold rolling, cut to length, cut to width, annealing, automation in steel coil processing, steel industry applications]