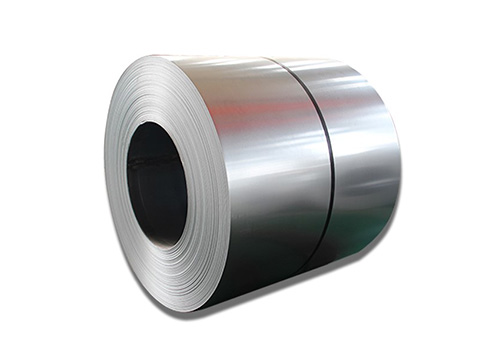

Eh, you know them coiled metal things? Well, it’s just metal, flat like, and they roll it up into these big ol’ coils. They say it’s the best way to keep it stored, ‘cause when it’s coiled up, you can save space. And moving it around? Oh, it’s much easier that way, too. I reckon if you had a big ol’ flat sheet of metal, it’d be a mess to haul. So, coiling it up like this sure helps, ya see?

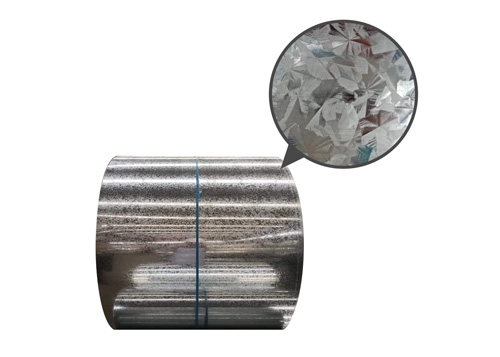

Now, lemme tell ya how they do it. When that metal’s all hot and fresh outta the mill, they start rollin’ it up. While it’s still soft and bendy, they wind it into these tight coils. Once it cools off, it stays coiled just like that. It ain’t just any ol’ thing either—this metal can get used for all sorts of stuff! You ever heard of them motors and transformers? Well, they use metal coils for that. And antennas, too! Them gadgets we got nowadays, they all need this coiled-up metal for somethin’ or other.

What’s it good for? Well, coiled metal is used all over, not just for them fancy electronics. They use it for roofs, siding, and all kinds of construction. If you look at them houses with metal roofs, I betcha that roof started out as a coiled-up sheet of metal. Even farmers use it, too! You see those barns with metal walls? Same deal. They unroll that coil, cut it up, and bam—there’s your barn wall or roof!

And in factories, they use them coils for even more stuff. It’s not just roofs and walls. They cut it up into smaller pieces, make pipes, and all kinds of parts. Factories need a lot of coiled metal ‘cause it’s strong and lasts long. And let me tell ya, they don’t let none of it go to waste. Every lil’ scrap gets used up.

Why coil it? Well, think about it—if ya had a long sheet of metal just layin’ flat, it’d take up a ton of space. But if you roll it up tight, you can fit way more in one place. It’s like rollin’ up a rug; it takes up way less room. And when they wanna use it, they just unroll what they need. It’s real handy, let me tell ya.

They also make different sizes of coils, too. Some are small, for little jobs, and some are big ol’ ones for the heavy-duty stuff. When they wanna cut it up, they just slice it into the width they need. It makes the work go faster, I reckon. And it’s strong, too—these coils can be made of steel or other metals, so they can handle tough jobs like a champ.

Who uses it? I already told ya ‘bout farmers and builders, but lots of folks use coiled metal. Ever see them big ol’ buildings in town? The kind with metal sides? Yep, that’s coiled metal right there. And in factories, they use it for machines, parts, and even tools. It’s everywhere once ya start lookin’! Metal roofs, walls, machines—all started from a coil. It’s amazin’ how much ya can do with it.

Even with all them fancy technologies now, we still need coiled metal. As life keeps gettin’ more modern, the need for coiled metal just grows. All them cars, gadgets, and even homes—they all got some coiled metal in there somewhere. It’s the kind of thing we don’t think about much, but we sure do rely on it every day.

In the end, coiled metal’s been around a long time, and it ain’t goin’ nowhere. As long as we keep buildin’ stuff and makin’ machines, coiled metal’s gonna be needed. And you can bet, they’ll keep on rollin’ it up, packin’ it tight, and sendin’ it all over the place. We wouldn’t get far without it, that’s for sure!

Tags: [coiled metal, metal roofing, steel coils, construction, manufacturing, electronics]