Speaking of cold-rolled steel coils, there are really some things to pay attention to. You know, cold-rolled steel coils are much more expensive than hot-rolled ones. Why are they expensive? This is because the production process is complicated, and they have to go through annealing and rolling. Although we don’t understand these high-tech things, we have heard that cold-rolled things are thin and have many uses, such as cars and home appliances.

The difference between cold rolling and hot rolling

If you ask me what the difference is between cold rolling and hot rolling, I will tell you that hot-rolled steel coils are heated first and then rolled. The temperature is high, the steel is soft and easy to process. But cold-rolled steel coils are different. They are hot-rolled first and then cold-rolled. The steel surface is smooth and hard. Don’t be fooled by the complicated process, the things made are very easy to use.

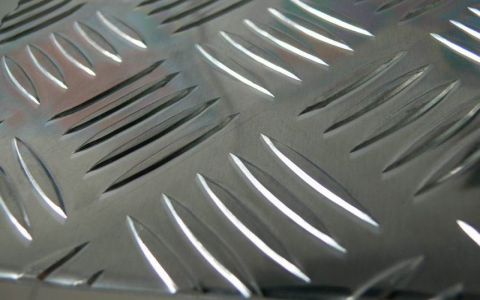

Cold-rolled steel is as thin as paper and very strong. Although it is more expensive, it is more worry-free when we use it. Some people say that cold-rolled steel has good quality and a smooth surface, and can be used in many high-end places, such as the shell of cars, the shell of home appliances, and even some building materials.

Production process of cold-rolled steel coils

How is this cold-rolled steel coil made? First hot-rolled, then cold-rolled. After cold rolling, it has to be annealed. Annealing is to make the steel softer so that it is easier to process. Finally, it is rolled to make the steel thinner and smoother. I heard that these steps are indispensable, and each step must be carefully operated, so that the steel produced can be used well.

First hot rolling, the temperature is high, the steel is soft and easy to process.

Then cold rolling, the temperature is low, the steel is hard, and the surface is smooth.

Annealing makes the steel softer and easier to process.

Finally rolling makes the steel thinner and smoother.

Each step must control the temperature and pressure well. If you are not careful, the quality of the steel will be bad. You see, this process is complicated, so it makes sense that it is expensive. Those factories strictly control each step to produce high-quality cold-rolled steel coils.

Application of cold-rolled steel coils

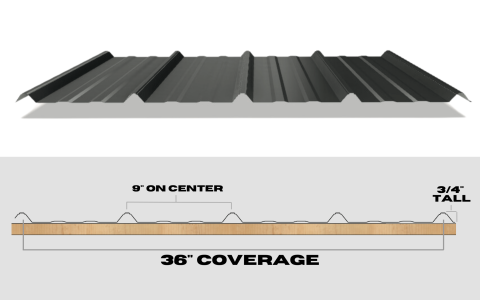

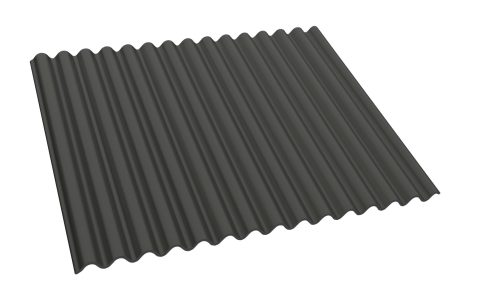

This cold-rolled steel coil has a wide range of applications. For example, many parts in automobile manufacturing use it; home appliance manufacturing, refrigerators, washing machines also use it. There are also some building materials and steel plates used for decoration, which are all cold-rolled. I heard that these steels have a smooth surface and high strength, which are particularly suitable for these places.

Although the price is a bit expensive, the quality is good and it is safe to use. Especially for automobiles, the body shell uses cold-rolled steel coils, which are both beautiful and durable. The same is true for home appliances, which have a smooth surface, are not easy to rust, and have a long service life. It is really expensive for a reason.

Although the production process of this cold-rolled steel coil is complicated and the price is expensive, it has good quality and is widely used. It is really a good thing. We don’t usually come into contact with these high-tech products, but knowing its benefits, we have a plan in our hearts.