Galvalume Coil: The Perfect Solution for Durability and Corrosion Resistance

Galvalume coil is a versatile and durable material used in a wide range of industries due to its exceptional resistance to corrosion and rust. The combination of aluminum, zinc, and silicon in its coating makes Galvalume coil a superior alternative to traditional galvanized steel, particularly in applications where long-term durability is essential. In this article, we will explore the benefits, uses, and reasons why Galvalume coil has become the preferred choice for many professionals. This article is optimized for SEO to provide valuable insights into Galvalume coil while helping you find the answers you need.

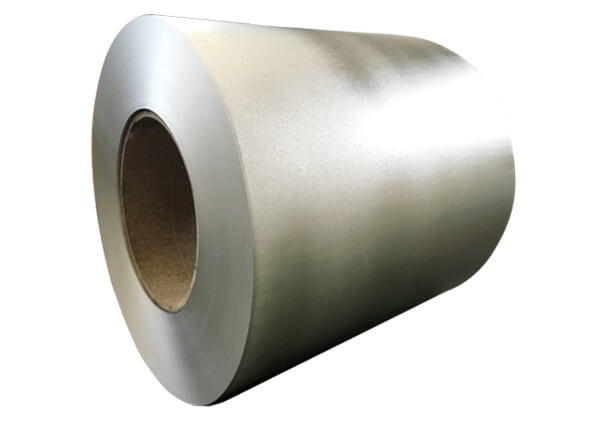

What is Galvalume Coil?

Galvalume coil is a type of steel coated with an aluminum-zinc alloy. The composition typically includes 55% aluminum, 43.4% zinc, and 1.6% silicon, creating a highly durable coating that offers better corrosion resistance compared to traditional galvanized steel. This unique alloy blend forms a protective layer on the steel surface, which helps protect it from the elements and slows down the corrosion process.

The manufacturing of Galvalume steel coil involves a continuous hot-dip process, ensuring an even and consistent coating. This process improves the material’s structural integrity and allows it to perform well in demanding environments. Over the years, Galvalume has become the go-to choice for roofing, siding, and other construction projects due to its cost-effectiveness and long-term durability.

Key Benefits of Galvalume Coil

1. Outstanding Corrosion Resistance

One of the primary benefits of Galvalume coil is its excellent corrosion resistance. The aluminum in the coating provides a barrier against moisture, which significantly reduces the rate of corrosion. The zinc adds a level of sacrificial protection that helps to preserve the steel, even in areas prone to scratches or damage. Together, these elements give Galvalume steel coil up to three times the corrosion resistance of standard galvanized steel.

2. Longer Lifespan

Galvalume coil offers an extended service life compared to other coated steel products. Its ability to resist corrosion ensures that it remains intact and functional for many years, making it ideal for long-term projects. In outdoor and highly corrosive environments, such as coastal areas or industrial zones, Galvalume’s lifespan can exceed 50 years with minimal maintenance.

3. Heat Reflectivity

Galvalume coil has excellent heat reflectivity, which makes it an energy-efficient material for roofing applications. By reflecting more sunlight than other materials, Galvalume helps maintain cooler building temperatures, reducing the need for air conditioning and lowering energy costs. This makes Galvalume particularly popular in regions with hot climates, where energy efficiency is a top priority.

4. Cost-Effective

Despite its superior performance, Galvalume coil remains a cost-effective material compared to alternatives like stainless steel or aluminum. The relatively low cost of production, combined with the material’s longevity, means lower long-term costs for maintenance and replacement. This makes it an attractive option for large-scale construction projects where budget and durability are both key factors.

5. Aesthetic Appeal

Galvalume coil has a smooth, shiny surface that can be visually appealing in both residential and commercial applications. It can be left unpainted for a modern, industrial look or coated with various finishes to meet specific design needs. The material’s flexibility in design makes it a popular choice for architects and builders looking to combine durability with visual appeal.

6. Eco-Friendly

Galvalume coil is fully recyclable, making it an environmentally friendly option for construction and manufacturing projects. Its long lifespan also reduces the need for frequent replacements, minimizing the environmental impact associated with producing new materials. As the demand for sustainable building materials grows, Galvalume coil’s eco-friendly properties make it a responsible choice for today’s green building initiatives.

Common Applications of Galvalume Coil

1. Roofing and Siding

One of the most widespread uses of Galvalume coil is in roofing and siding for residential, commercial, and industrial buildings. Its corrosion resistance and heat reflectivity make it a perfect material for metal roofs and wall cladding. In coastal regions or areas with harsh weather conditions, Galvalume steel provides a long-lasting solution, keeping buildings safe and energy-efficient.

2. Construction

Beyond roofing, Galvalume coil is widely used in various construction applications, including structural framing, cladding, and panels. Its ability to withstand environmental stress makes it ideal for buildings exposed to extreme weather, such as factories, warehouses, and other industrial structures. Galvalume’s long-term durability reduces the need for costly repairs and replacements, offering both reliability and cost savings for builders.

3. Automotive Industry

The automotive industry also utilizes Galvalume steel coils in the production of body panels, undercarriages, and other vehicle components. The material’s corrosion resistance is critical in regions where vehicles are exposed to road salts, moisture, and other corrosive elements. Galvalume’s strength and lightweight properties contribute to better fuel efficiency and longer-lasting vehicle parts.

4. Appliance Manufacturing

Household appliances, such as refrigerators, ovens, and washing machines, often incorporate Galvalume steel for their exterior casings. The material’s resistance to corrosion and rust ensures that appliances retain their appearance and functionality over time, even in humid environments. Galvalume steel’s sleek finish also contributes to the modern, polished look of many household products.

5. Agricultural Equipment and Buildings

Farm equipment, silos, barns, and storage units benefit from Galvalume steel’s corrosion-resistant properties. Agricultural environments often expose materials to moisture, chemicals, and the elements, making Galvalume a reliable choice for long-lasting structures. The material’s resistance to rust helps protect valuable equipment and produce, ensuring durability in challenging conditions.

Factors to Consider When Buying Galvalume Coil

1. Coating Thickness

The thickness of the aluminum-zinc coating is critical to the performance of Galvalume steel coil. Thicker coatings provide better corrosion resistance, especially in harsh environments. Coating thickness is typically measured in grams per square meter (gsm), with higher values indicating more robust protection.

2. Base Steel Quality

The base steel used in the Galvalume coil affects its mechanical properties, such as strength and flexibility. Ensure that the steel meets the requirements of your application, whether you need high tensile strength or malleability for specific forming or bending processes.

3. Surface Finish

Galvalume steel coils come in various surface finishes, including smooth, matte, or spangle finishes. Each finish is suited for different applications and aesthetic preferences. A smooth finish is ideal for projects where appearance is important, while a spangled finish might be preferred for industrial uses.

4. Paintability

If you plan to paint the Galvalume steel, ensure that it is suitable for coating. Many manufacturers offer pre-painted Galvalume coils that come ready for installation, saving time and effort in the finishing process.

5. Supplier Reputation

Working with a reputable supplier is essential to ensure that you receive high-quality Galvalume steel coils that meet industry standards. Look for suppliers with a proven track record of providing durable, consistent products that comply with regulations such as ASTM A792 (for the U.S.) or EN 10346 (for Europe).

Conclusion

Galvalume coil is a superior material known for its excellent corrosion resistance, long lifespan, and versatility. Whether for roofing, construction, automotive, or appliance manufacturing, Galvalume steel offers a reliable and cost-effective solution that outperforms many other materials. Its unique combination of aluminum, zinc, and silicon creates a protective barrier that ensures durability, even in harsh environments.

As sustainability becomes more important in modern industries, Galvalume coil stands out as an eco-friendly and recyclable option that aligns with green building standards. With its range of benefits, from aesthetic appeal to energy efficiency, Galvalume coil is an ideal choice for projects requiring both durability and design flexibility.

Investing in Galvalume coil ensures long-term performance, reduced maintenance costs, and a sustainable approach to construction and manufacturing.