Galvanized Coil: The Ultimate Guide to a Durable and Versatile Material

Galvanized coil is a fundamental material in various industries, prized for its durability, corrosion resistance, and versatility. From construction to automotive, galvanized coils play a pivotal role in applications where both strength and protection are essential. This article provides a comprehensive overview of galvanized coils, exploring their benefits, uses, and why they have become a preferred choice in modern manufacturing. Whether you’re a builder, an engineer, or simply curious about industrial materials, this guide offers everything you need to know about galvanized coils while being optimized for Google SEO standards.

What is Galvanized Coil?

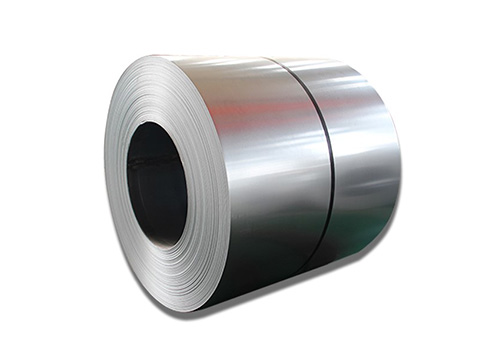

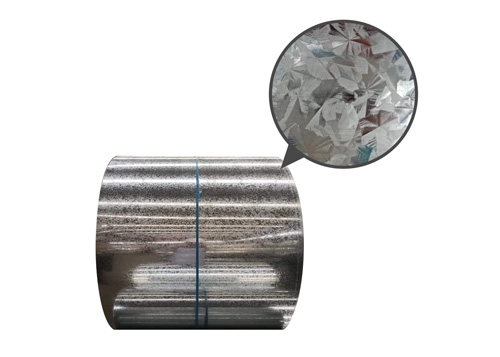

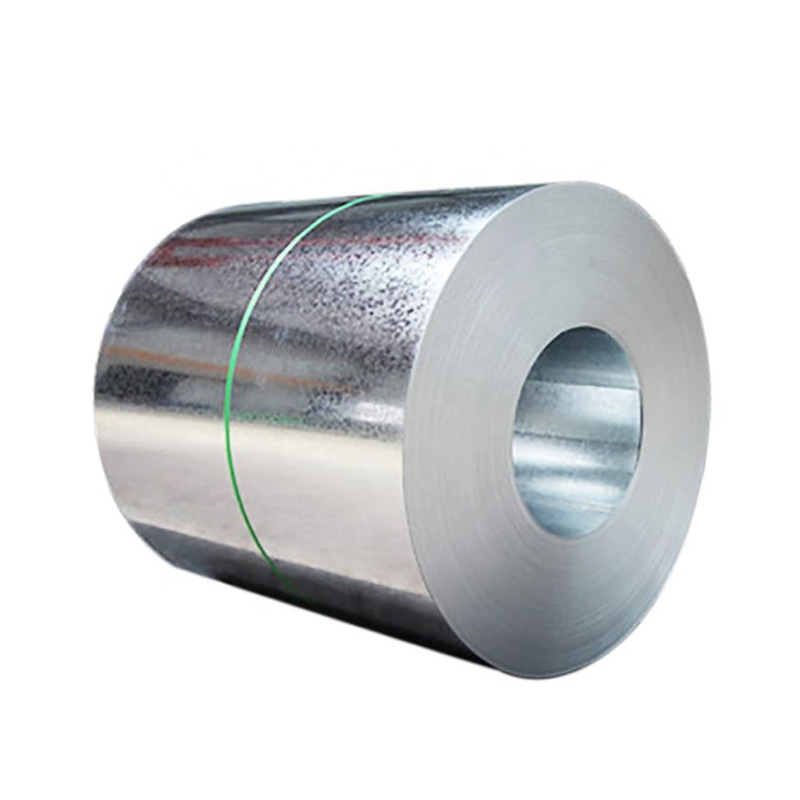

A galvanized coil is a steel product coated with a layer of zinc through a process called galvanization. This zinc coating protects the steel from corrosion and rust, making it ideal for use in environments where moisture or other corrosive elements are present. Galvanization occurs through hot-dip galvanizing or electro-galvanizing.

The result is a material that combines the strength and malleability of steel with the protective properties of zinc, ensuring long-lasting performance.

Benefits of Galvanized Coil

1. Exceptional Corrosion Resistance

One of the primary reasons for using galvanized coils is their ability to resist rust and corrosion. The zinc coating forms a protective barrier between the steel and the environment, preventing rust even in humid or marine climates. This makes galvanized coil an excellent choice for outdoor applications or environments where exposure to water or chemicals is frequent.

2. Cost-Effective

Compared to other corrosion-resistant materials such as stainless steel or aluminum, galvanized coils offer a more affordable option without compromising performance. The galvanization process is less costly than producing stainless steel, and because galvanized steel requires little maintenance, it provides significant long-term cost savings.

3. Durability and Longevity

Galvanized steel coils have a long service life. The zinc coating not only protects the steel from corrosion but also heals itself if scratched, extending the life of the material. In many cases, galvanized steel can last 50 years or more, especially in environments with less aggressive atmospheric conditions.

4. Versatility

Galvanized coil is versatile, available in various thicknesses, widths, and grades to suit different applications. Whether it’s used for industrial, commercial, or residential purposes, this material can be customized to meet specific needs. Additionally, galvanized coils can be painted or coated to match aesthetic requirements.

5. Eco-Friendly

Steel, including galvanized steel, is 100% recyclable. When a galvanized coil reaches the end of its useful life, it can be melted down and reused, reducing the demand for raw materials and lowering carbon emissions associated with steel production. This makes galvanized coil a sustainable choice in today’s eco-conscious industries.

Common Applications of Galvanized Coil

1. Construction

Galvanized coils are extensively used in the construction industry for structural and non-structural purposes. They are commonly used in roofing, wall panels, fencing, and cladding. The corrosion-resistant properties of galvanized steel ensure that buildings and structures remain durable and protected from environmental factors such as rain, wind, and pollution.

2. Automotive

In the automotive industry, galvanized steel is used for body panels, undercarriages, and frames. The automotive sector values galvanized coils for their lightweight strength and resistance to rust, ensuring vehicle parts maintain their integrity over time. Rust-resistant materials are critical for vehicle safety and longevity, especially in regions that use road salts in winter.

3. Appliance Manufacturing

Many household appliances such as refrigerators, washing machines, and air conditioning units feature galvanized steel parts. The material’s rust resistance ensures that these appliances last longer, especially in high-moisture areas such as kitchens and bathrooms. Moreover, the smooth finish of galvanized steel is ideal for appliance exteriors, giving them a sleek, modern look.

4. Agriculture

In agriculture, galvanized coils are used for building barns, silos, grain bins, and other farm structures. The material’s resistance to harsh outdoor conditions makes it perfect for rural and agricultural environments where exposure to the elements is unavoidable. Galvanized steel also plays a role in producing fencing and tools essential to farming operations.

5. Energy and Utilities

The energy sector utilizes galvanized coils in power plants, transmission towers, and other infrastructure. The corrosion-resistant properties are crucial for the longevity of these structures, which are often exposed to harsh environmental conditions. Galvanized steel helps ensure that energy delivery remains stable and secure over long periods.

Factors to Consider When Choosing Galvanized Coil

When selecting a galvanized coil for your project, several factors need to be considered:

1. Coating Thickness

The thickness of the zinc coating is a significant determinant of the coil’s corrosion resistance. Thicker coatings offer better protection, especially in highly corrosive environments such as coastal areas. The coating weight is typically measured in grams per square meter (gsm), with higher numbers indicating thicker layers.

2. Base Material Quality

The quality of the steel used in the galvanized coil affects its overall performance. Ensure that the steel base meets the mechanical properties required for your specific application, such as tensile strength and elongation capacity.

3. Surface Finish

Galvanized coils come in various surface finishes, including regular spangle, zero spangle, and matte. Each finish is suited for different applications. For example, a regular spangle finish is commonly used in construction, while a zero spangle finish may be preferred for visible surfaces or painted applications.

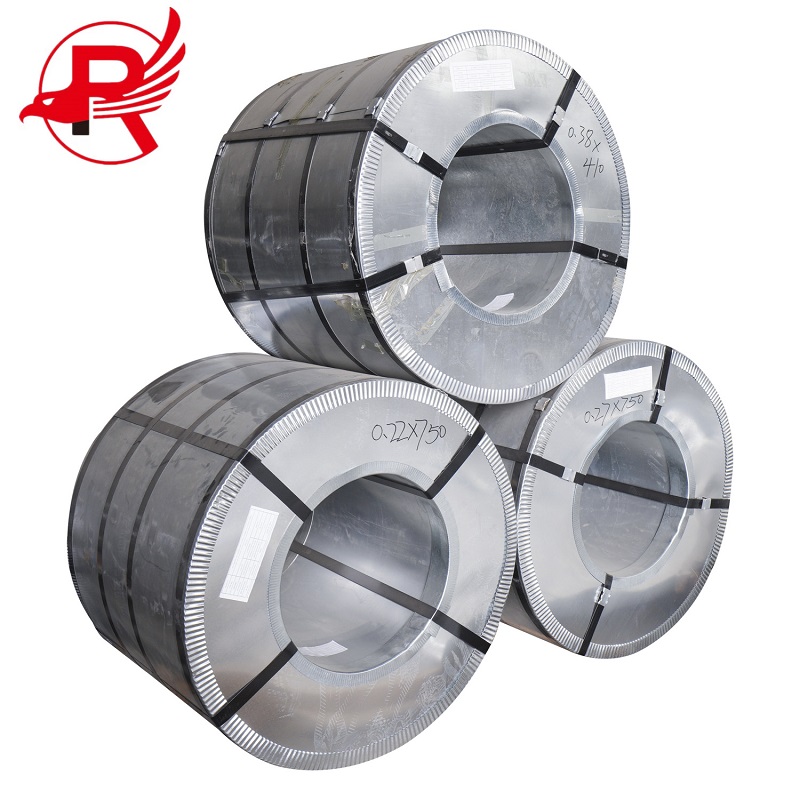

4. Coil Dimensions

Ensure that the galvanized coil’s thickness, width, and length align with your project requirements. Manufacturers can often customize these dimensions based on your specific needs, ensuring you get a product tailored to your project.

5. Compliance with Standards

Choose galvanized coils that comply with industry standards, such as ASTM A653 in the United States or EN 10346 in Europe. These standards guarantee that the steel coil meets minimum performance and safety criteria.

Why Galvanized Coil is an Industry Leader

Galvanized coil has proven itself as a reliable, versatile material in various industries due to its combination of strength, cost-effectiveness, and corrosion resistance. Its ability to withstand harsh environments makes it ideal for projects where longevity and durability are critical. Moreover, its recyclability and eco-friendliness make it a responsible choice in today’s push for sustainability.

The global demand for galvanized coil continues to rise, fueled by its widespread use in essential industries like construction, automotive, and manufacturing. Whether for large-scale industrial applications or small household appliances, galvanized coil provides a high-performance, long-lasting solution that stands the test of time.

Conclusion

Galvanized coil is a vital material that offers a range of benefits including corrosion resistance, durability, cost-effectiveness, and versatility. With its wide applications across industries such as construction, automotive, and appliance manufacturing, galvanized coil remains an industry staple. Its recyclability and alignment with sustainable practices further enhance its appeal in today’s environmentally conscious world.

By selecting galvanized coil for your project, you ensure long-term performance, reduced maintenance costs, and reliable protection against environmental factors. Whether you’re building infrastructure, manufacturing vehicles, or designing appliances, galvanized coil is the material of choice for modern engineering and design needs.