Well now, let’s talk about this galvanizing thickness thing. I ain’t no fancy engineer or nothin’, but I know a thing or two about keeping things from rustin’. You see, out here in the country, we gotta make things last. Can’t be replacin’ stuff every year, ya know?

So, this galvanizin’, it’s like puttin’ a coat of armor on your metal. Keeps the rain and the snow and all that nasty stuff from eatin’ away at it. And the thicker that coat is, the longer it’ll last. That’s just common sense, ain’t it?

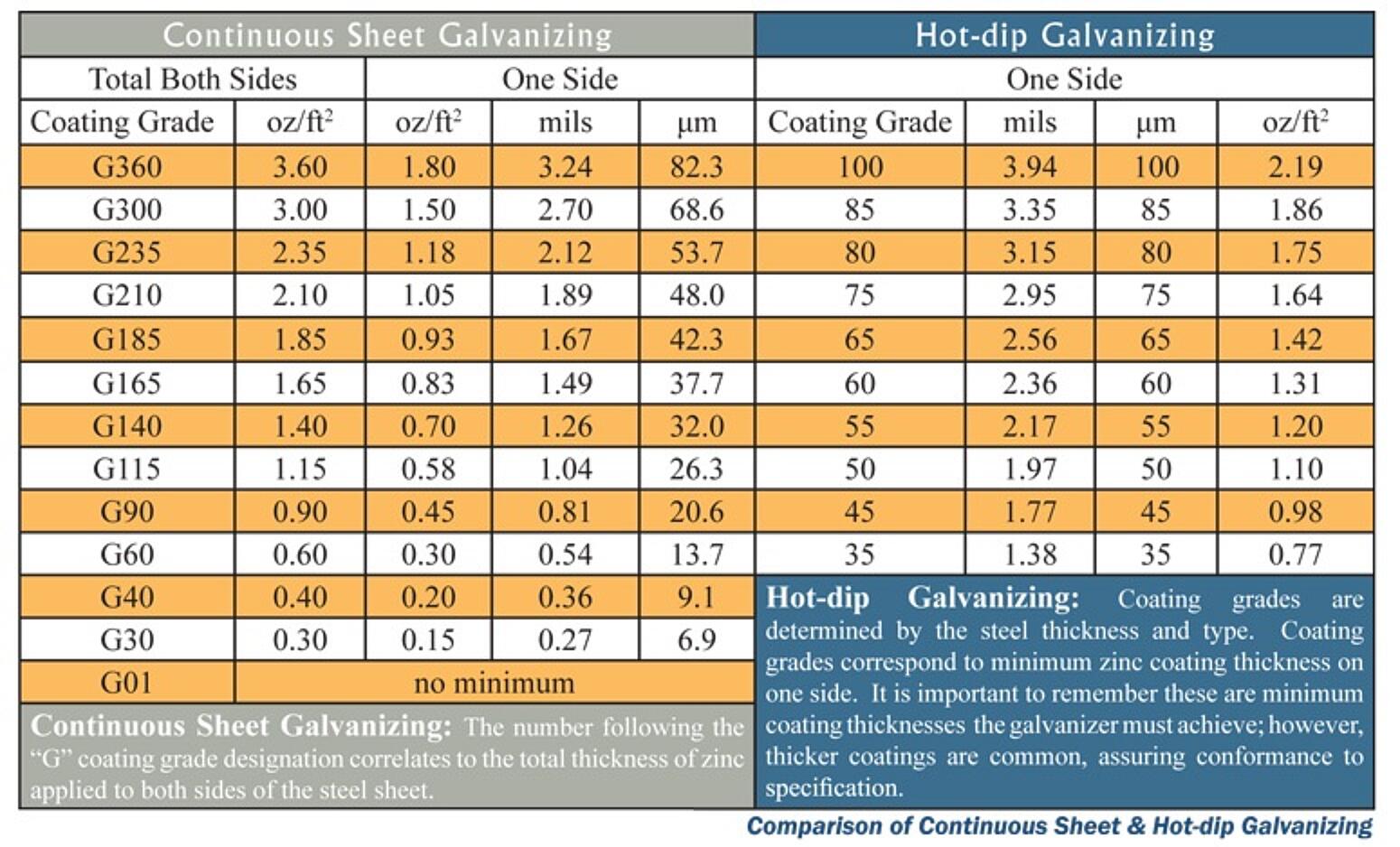

Now, they got all these big words and numbers and stuff, like this ASTM A123. Sounds mighty important, I reckon. But from what I gather, it’s just a way of sayin’ how thick that coat of zinc gotta be. They talk about “hot-dip” galvanizin’, which just means they dunk the metal in a big ol’ pot of hot melted zinc. Kinda like fryin’ chicken, only with metal.

- Hot-dip is important, ya gotta make sure it’s dipped good.

- Thickness matters, thin coat ain’t gonna do ya much good.

- Coating quality, gotta make sure it’s smooth and even, no bubbles or nothin’.

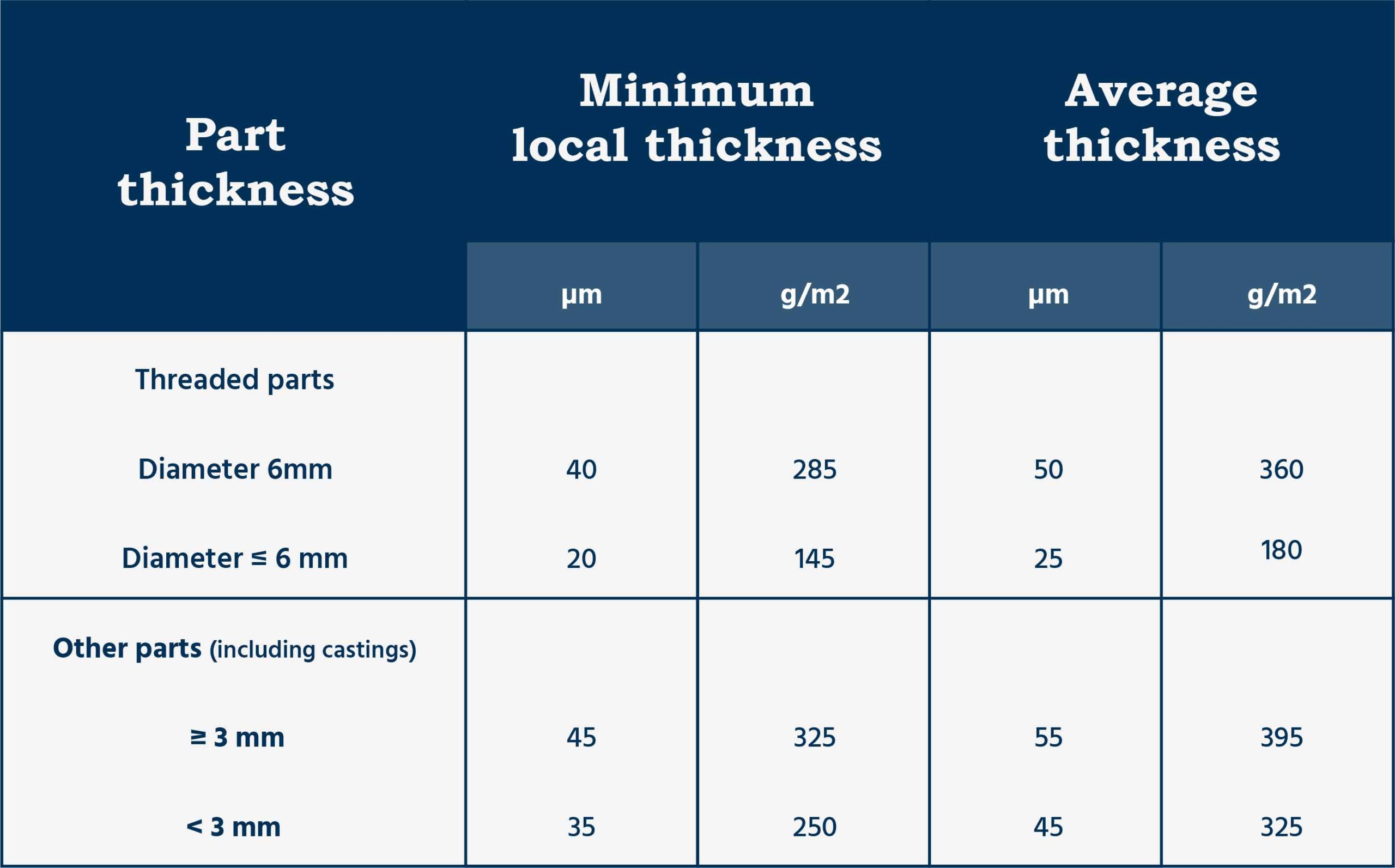

They measure this thickness in somethin’ called “microns.” Don’t ask me what a micron is, sounds like somethin’ a bug would eat. But the bigger the number, the thicker the coat, that’s all I need to know. And they measure it in somethin’ else too, “grams per square meter” they call it. More grams, more zinc, thicker coat. See? It ain’t rocket science.

Now, if you’re buildin’ somethin’ outta steel, like a gate or a fence or somethin’, you want that galvanizin’ to be good and thick. Especially if it’s gonna be out in the weather all the time. Them city folks, they got their fancy standards and rules, like this AS/NZ 4680:2006 they talk about. That’s just their way of makin’ sure everythin’s done right, I guess. They got standards for all sorts of stuff, even the kind of steel you use. Says somethin’ about the steel makin’ a difference to the galvanizin’. Well, I always say, start with good stuff, end with good stuff. Makes sense, don’t it?

And it ain’t just about how thick the zinc is, it’s about how well it sticks to the metal too. You gotta clean that metal good before you dip it, get all the rust and dirt and grease off. Otherwise, that zinc ain’t gonna stick right, and it’ll flake off and you’ll be back to square one with rust all over the place. Just like paintin’ a fence, gotta clean it first.

Design matters too, they say. If you got a bunch of corners and crevices and stuff, it’s harder to get a good, even coat of zinc. So, you gotta think about that when you’re buildin’ somethin’. Try to keep things simple and smooth, that’s what I always say. Easier to build, easier to galvanize, easier to keep from rustin’.

So, there you have it. Galvanizing thickness, it ain’t so complicated after all. Just gotta make sure you got a good thick coat of zinc, it sticks good to the metal, and you start with good quality stuff. And remember, the thicker the better, especially if you want it to last.

And one more thing, don’t go skimpin’ on the galvanizin’. It might cost a little more upfront, but it’ll save you money in the long run. ‘Cause you won’t be replacin’ rusty stuff all the time. That’s what my old pappy always said, “Do it right the first time, so you don’t gotta do it again”. He was a smart fella, that pappy of mine.

Tags: [galvanizing, thickness, hot-dip, zinc coating, ASTM A123, AS/NZ 4680:2006, steel, corrosion protection, metal coating, durability]