Coil processing lines, ya see, they’re somethin’ mighty important if ya work with metal. These lines, well, they take big ol’ rolls of metal, or what folks like to call “coils,” and get ‘em all sorted out and ready for whatever work ya need. Now, I may not be a fancy engineer, but I’ll tell ya how it’s done in a way us plain folks can understand.

What’s This Coil Processing All About?

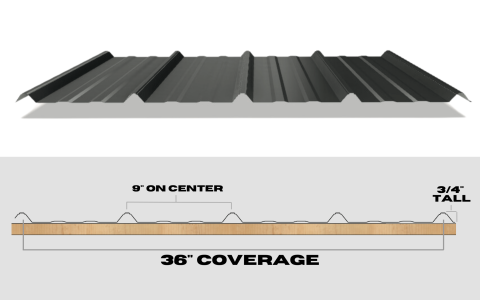

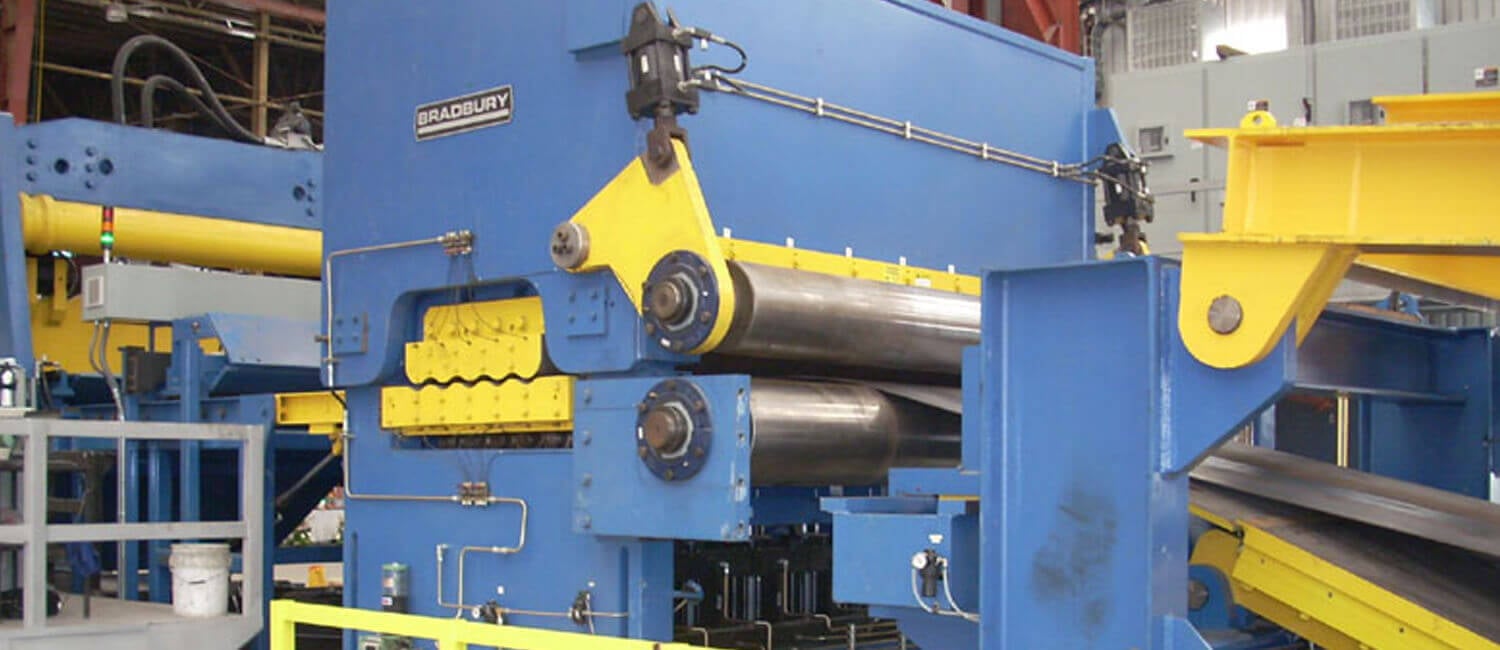

So, these coil processing lines, they’re like a chain o’ machines all lined up, and each one’s got a job to do. Picture this – ya got a big metal roll, and first up, they cut it, maybe flatten it if that’s what’s needed, and they can even clean it up a bit. That way, by the end, the metal’s all fixed up, ready for whatever someone wants to make out of it – be it cars, appliances, or even the roof ya got over yer head.

Different Types of Coil Processing Machines

Now, let me tell ya, not all these lines are the same. Naw, they got all kinds, dependin’ on what kinda work folks need done:

- Slitting Lines: These here machines take that big ol’ metal roll and slice it up nice and thin. They cut it into smaller pieces, right down to the width folks need for their work.

- Cut-to-Length Lines: Now, sometimes ya don’t need thin strips, ya just need flat sheets. So these machines go and cut that coil right down to the length and size that’s ordered, stackin’ ’em up like a pile o’ pancakes, all ready to go.

- Recoiling Lines: For folks wantin’ a fresh coil, these machines take the metal, fix it up and wind it back up nice ‘n neat.

Why Custom Designs Are Needed

Now here’s somethin’ interesting – no two factories need the same exact line. That’s where these fancy custom designs come in handy. Ya see, these machines gotta fit just right, like how ya can’t wear just any ol’ shoes and expect ‘em to be comfy. Same with these lines! Some companies are real experts at makin’ custom setups, fit just right for any type o’ metal processin’ needs. They’ll figure out all the details – mechanical, electrical, you name it – to build a line from scratch so it does exactly what the job calls for.

Automated Coil Handling

Now, ya might think, “who’s gonna lift them heavy coils and move ‘em ‘round?” That’s where the automated coil handling comes in, savin’ folks the trouble. Big machines with all kinds o’ gadgets handle that coil, movin’ it from one end o’ the line to the other, and nobody has to break a sweat. Machines can do it all safe ‘n steady, keepin’ things rollin’ right along.

Benefits of Good Coil Processing Lines

A good coil processing line, lemme tell ya, it makes all the difference:

- Efficiency: It gets the job done faster, which means more parts ready for sale or makin’ things.

- Cost Savings: More efficient machines mean less waste, and less waste means fewer costs all around.

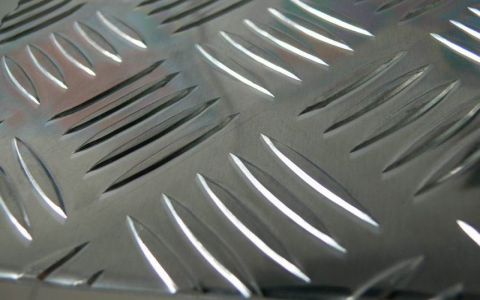

- Quality Control: With these high-tech gadgets, they can keep an eye on quality, makin’ sure every piece o’ metal comes out lookin’ just like it should.

Who Needs These Processing Lines?

Lots of folks, lemme tell ya! Any place makin’ somethin’ from metal’s gonna need one. Think big factories for car parts, appliance makers, and even places makin’ metal sheets for buildin’ materials. All over the world, they got these lines in place, just crankin’ out metal parts day in, day out.

Installation and Setup

Settin’ up a coil processing line ain’t no small task. Ya need professionals to put it all together – they gotta install it right, get every machine workin’ smooth as butter. Some companies even offer full setups – from pickin’ the right machines to installin’ ‘em, all the way to startin’ ‘em up. They’ll run it all to make sure it’s ready to go before handin’ over the reins.

Keeping Up with Technology

Now, metalworkin’ ain’t what it used to be. New gadgets, new machines keep comin’ out, all designed to do things faster and with less fuss. That’s why so many folks are always lookin’ to upgrade their lines, maybe add a new piece or two. These companies workin’ with coil lines are stayin’ sharp, always lookin’ for ways to make things better, faster, and smoother.

The Future of Coil Processing Lines

Lookin’ ahead, it’s pretty clear that these lines ain’t goin’ nowhere. With so much buildin’ and makin’ goin’ on all over, these machines are here to stay. More automation, better precision, maybe even smarter machines – that’s the future, and folks are all set to see where it’ll go. So, coil processing lines, well, they’re gonna keep crankin’ out metal parts for a good long while, no doubt ‘bout it.

Tags: [coil processing, metal coils, slitting lines, cut-to-length, automated coil handling, custom coil equipment]