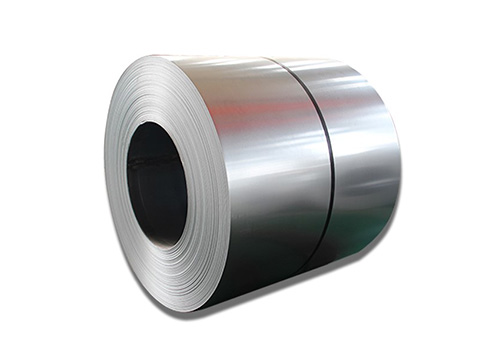

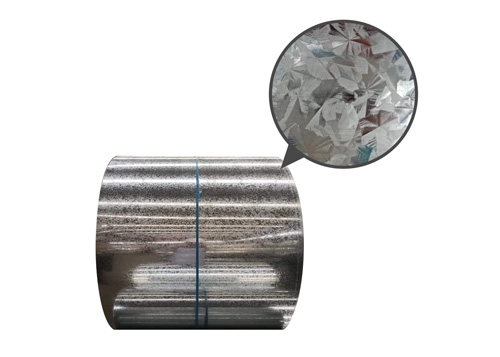

Now, lemme tell ya about this hot-dipped steel business, alright? They got this whole process to keep the steel from rustin’ away, and what they do is they dunk it in this hot melted zinc, ya see. This here zinc, it’s like a coat on top of the steel, keepin’ the water and air from eatin’ away at it. It’s all to stop that rust, plain and simple.

Now, they got a name for it too. Fancy folks call it hot-dip galvanizing. What they do, they take that steel and plop it down in this hot bath of zinc, and it sticks right to the steel like mud on a pig’s back. The zinc, once it cools, makes a thick coat, thicker than if they just gave it a quick dip. That thick coat, that’s what makes this hot-dip process special, ya know. Helps the steel last longer, don’t let it rust so quick, even if it’s out in the rain and whatnot.

Why use hot-dipped steel? Well, if you want that steel to hold up in the weather, you don’t want no rust or wear and tear takin’ it down. Hot-dip makes sure of that, ‘cause this here zinc coat keeps it all protected. Some folks try other methods, but nothin’ beats this hot-dip. They got what they call “pre-galvanizing,” where they just dunk it in and pull it out real quick. Doesn’t make the coat thick enough to last, though. So, if ya want somethin’ tough and ready to handle whatever comes, hot-dip’s the way to go.

So how they do it? Well, first, they clean the steel all proper. Any dirt or oil, they scrub it right off, ‘cause that zinc needs a good clean surface to stick to. Once it’s cleaned up, they dip it in some chemicals to make sure the zinc grabs on nice and strong. Then they heat that zinc up till it’s all melted, and they dunk the steel in there. At around 450 degrees Celsius (that’s mighty hot!), that zinc just sticks right onto the steel and won’t let go.

Benefits of hot-dipped steel

- Lasts longer – That thick zinc coat keeps it from rustin’ away too quick.

- Cost-effective – Even though it might cost a bit up front, it saves ya money in the long run ‘cause it don’t wear out fast.

- Strong bond – That zinc coat bonds so well it’s like it’s part of the steel itself.

- Easy maintenance – Once it’s coated, you ain’t gotta fuss with it for years.

So ya might be wonderin’, where do folks use this hot-dipped steel? Well, it’s everywhere. They use it in buildings, ‘specially them big ol’ steel structures, and bridges too. Anything that sits out in the open, they’ll coat it so the rain don’t ruin it. Even in cars and tractors, you’ll see bits and pieces covered in hot-dip zinc. You leave steel out without that coat, it’ll rust quick as a fox, but this hot-dip makes sure it don’t.

Hot-Dip Galvanized Steel vs. Other Galvanizing

Now, there’s other ways folks try to keep steel from rustin’, but hot-dip’s the best, ya know. There’s a thing called electro-galvanizing, where they just give it a real light coat with electric charges. It’s cheaper, sure, but that coat’s so thin, it ain’t gonna last as long, specially not out in the rain. Then there’s pre-galvanized steel, like I was sayin’. They dip it quick, and it don’t give that thick coat like hot-dip. It’s alright for things that don’t need to stay strong in the weather, but if you got somethin’ important, you’re better off with hot-dip.

So in the end, if ya need steel that won’t quit on ya, hot-dip galvanized steel’s where it’s at. That thick zinc coat ain’t just sittin’ on top; it’s bonded right there with the steel. Makes it last and keeps ya from worryin’ about it rustin’ away. Whether it’s for bridges, barns, cars, or anythin’ out in the open, this here hot-dipped steel is what ya want. Don’t be skimpin’ when it comes to somethin’ that’ll hold up strong for years, alright?

Tags:[hot-dipped steel, hot-dip galvanizing, zinc coating, corrosion protection, rust prevention]