Well, howdy there! Let’s talk about this hot rollin’ thing, ya know, the one they do with metal. I ain’t no engineer, but I’ve seen things and heard stuff, so I’ll tell ya what I know.

What in the world is hot rollin’?

It’s like makin’ dough, but with metal. They heat that metal up real hot, hotter than a summer day in July, I tell ya. Hotter than my oven when I bake them pies! And then, they squish it, roll it, and make it into somethin’ new. It’s all about changin’ the shape, ya see? Make it thinner, longer, whatever they need.

Why they gotta heat it up so darn hot?

Well, they say it’s gotta be hotter than its “re-crystal…re-crys… somethin’ like that” temperature. Sounds fancy, huh? Basically, it means the metal gets soft and bendy like warm butter. That way, it don’t crack or break when they start rollin’ it. Smart folks figured that out, I reckon.

How they do this hot rollin’ thing, step by step?

Now, this ain’t somethin’ you do in your backyard, mind you. It’s a big deal, a whole process.

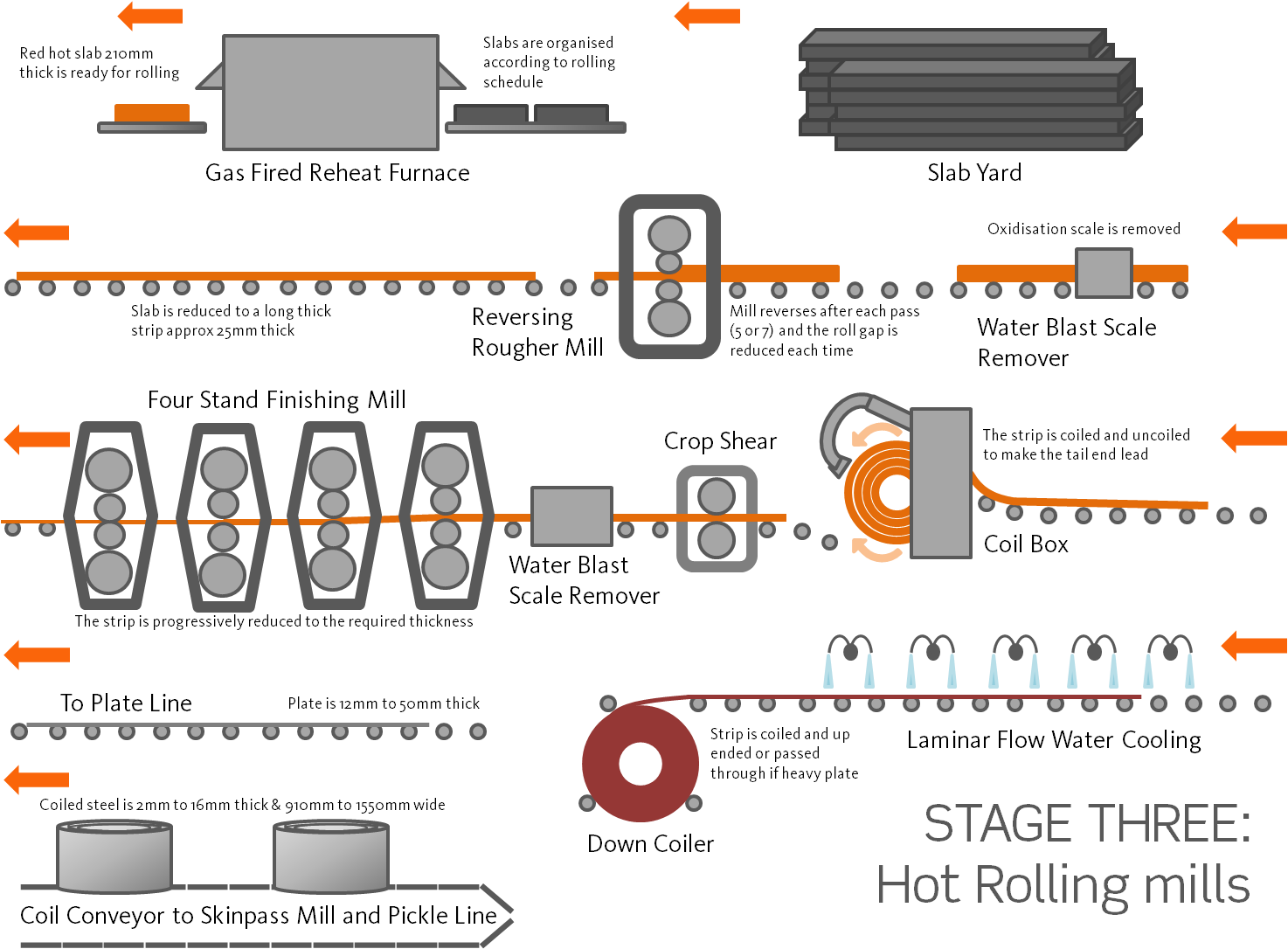

- First, they gotta get that metal ready. They call it “conditionin’,” which is just a fancy way of sayin’ they clean it up. Grind off the rough spots, make it smooth. Like when I clean the potatoes before I cook ’em, ya know?

- Then, they heat that sucker up. Like I said, real hot. They got big furnaces for that, hotter than anything you ever seen. They gotta make sure the whole thing is the same heat, not hot in one spot and cold in another. Like bakin’ a cake, gotta have even heat, or it won’t turn out right. This even heatin’ is important for what they call “temperature distribution”, makes sure the rollin’ goes smooth.

- Next, they get rid of the scales. When metal gets that hot, it gets all scaly and rough. They gotta clean that off before they roll it, or it’ll mess things up. They call it “descalin’.” Sounds important.

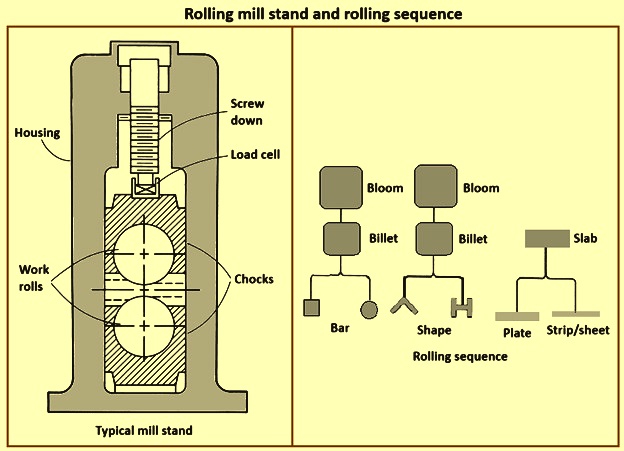

- Now comes the rollin’. They got these big rollers, like giant rolling pins, and they squeeze that hot metal through ’em. Squeeze it over and over, makin’ it thinner and longer each time. This part is all about “deformation patterns”, how the metal changes shape, they say. Sounds complicated, but it’s just squishin’ and stretchin’.

- They keep rollin’ it till it’s just the right size. They call it rollin’ down to the final diameter, whatever that means. They gotta be precise, I guess. Like when I’m measurin’ flour for my biscuits, gotta get it just right.

- Finally, they finish it up. They trim it, cut it, and make it all neat and tidy. They call it “trimmin’, slittin’, and cuttin’.” Like when I trim the edges of my pie crust, make it look pretty.

What kind of stuff they make with hot rollin’?

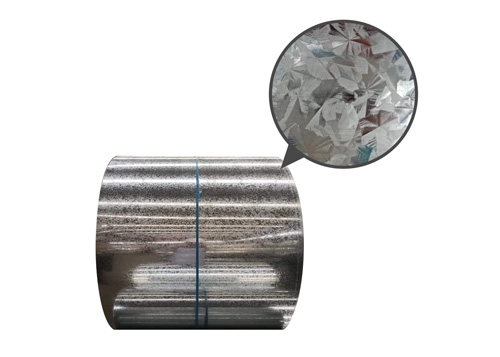

Oh, all sorts of things. Wires, sheets, plates of metal. Stuff they use to build bridges and buildin’s and cars and who knows what else. It’s important stuff, this hot rollin’. They gotta control the whole thing, from the heatin’ to the rollin’. They call it “control of transformation” or somethin’. Sounds like a lot of work to me, but them fellers know what they’re doin’. And this “metallurgical mechanisms of recovery and recrystallization”, that’s just the metal gettin’ soft again after bein’ squeezed, like a good dough after ya knead it. It helps to shape and reshape the stuff. It’s all about how the metal behaves when it’s hot, see? They gotta understand that to make good strong metal.

Hot rollin’ versus cold rollin’ – what’s the diff?

Now, they also got somethin’ called “cold rollin’,” but that’s a whole different story. That’s when they roll the metal when it ain’t so hot. It makes the metal stronger, but it’s harder to do. Like tryin’ to roll out cold dough, it ain’t easy. But we’re talkin’ about hot rollin’ today, so I won’t get into that cold stuff.

So, that’s hot rollin’ for ya, in a nutshell.

It’s a big, fancy process, but it’s just about heatin’ up metal and squishin’ it into the shape you want. It ain’t rocket science, but it ain’t somethin’ you can do with just a hammer and a fire, neither. Takes big machines, smart folks, and a whole lot of heat. They use math and models to figure it all out, like how the heat spreads and how the metal will bend. They call it “mathematical modeling”. Fancy, huh? But in the end, it’s all about makin’ strong, useful pieces of metal. And that, my friends, is what I know about hot rollin’. Hope it made some sense to ya. Now, if you’ll excuse me, I gotta go check on my own hot rollin’ project – got some biscuits in the oven!