Alright, let’s talk about how to measure them galvanized pipes. You know, the kind they use for all sorts of stuff around the house and farm. It ain’t rocket science, but you gotta do it right so you don’t end up with a pipe that’s too big or too small.

First off, you gotta get yourself some tools. Don’t go tryin’ to eyeball it, that ain’t gonna work. You’ll need a tape measure, the kind that rolls up, or maybe one of them fancy calipers if you got one. A caliper is real good for gettin’ precise measurements, you know, the kind that’s spot on. A tape measure works just fine too, though, specially for the bigger pipes.

- Tape Measure: For when you need to measure around the pipe or for longer lengths.

- Calipers: Best for when you need a super accurate measurement, especially for the pipe’s thickness or diameter.

- Pipe Measuring Tool: If you got one of them fancy ones, that’s good too, makes it a bit easier.

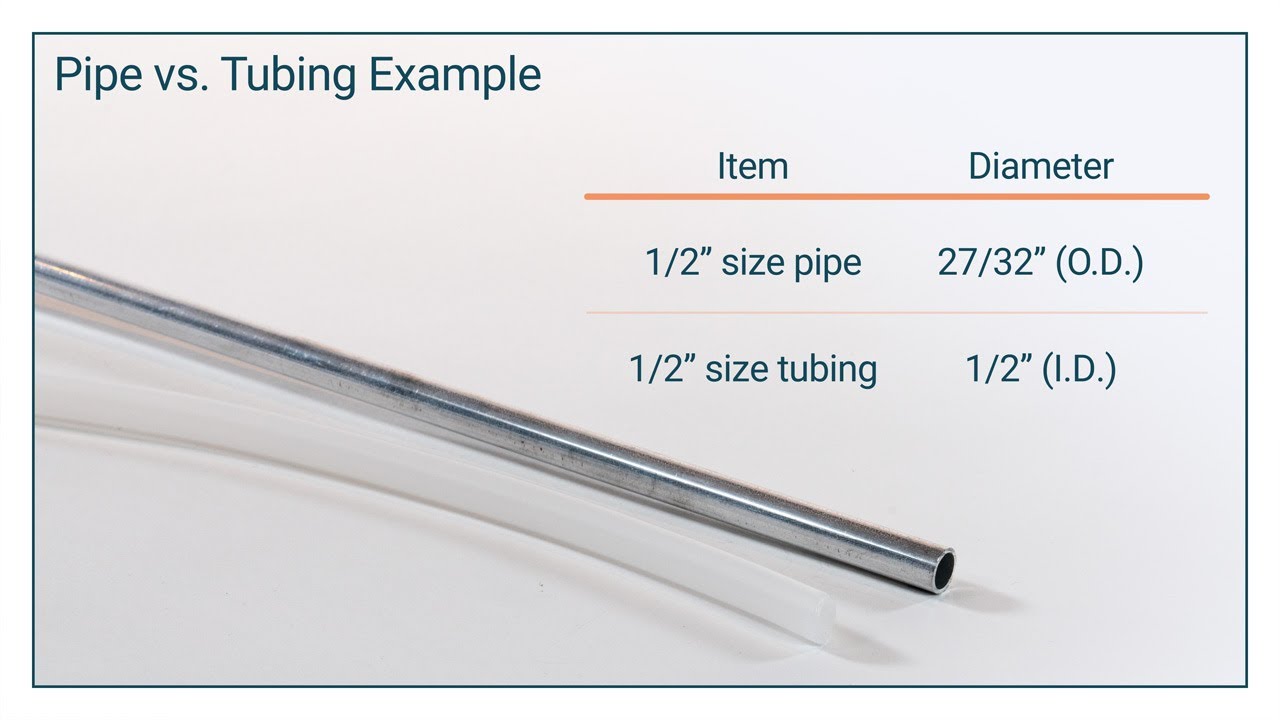

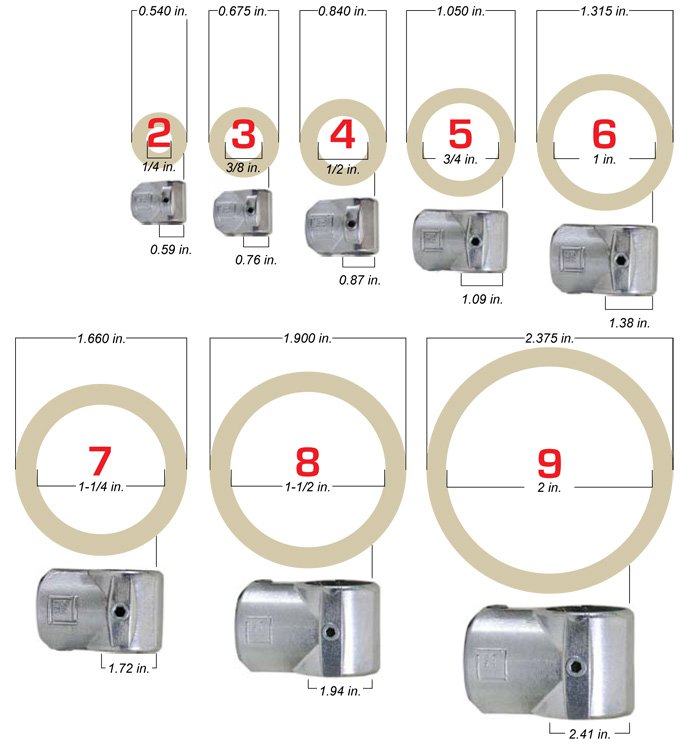

Now, the first thing you gotta figure out is what you’re tryin’ to measure. You see, there’s the outside diameter (OD), that’s how wide the pipe is from one side to the other, on the outside. And then there’s the inside diameter (ID), that’s how wide it is on the inside. And don’t forget the thickness, that’s how thick the metal of the pipe is. Sometimes that galvanized coatin’ adds a bit, so you gotta keep that in mind.

Let’s start with the outside diameter, the OD. If you can get to the end of the pipe easy-peasy, just stick your tape measure across the end, right through the middle. That’ll give you the OD. But, if the pipe’s already hooked up, or you can’t get to the end, you gotta do it a different way. You take your tape measure and wrap it around the pipe, like you’re givin’ it a hug. Get the circumference, that’s the measurement all the way around. Then, you take that number and divide it by 3.1416. Yeah, I know, sounds complicated, but it ain’t. That number, 3.1416, that’s what they call pi, it’s a special number for circles and such. Divide the circumference by that, and you get your OD.

How to measure the OD with a tape measure:

- Wrap the tape measure around the pipe to get the circumference.

- Divide the circumference by 3.1416.

- The result is the outside diameter (OD).

Next up is the inside diameter, the ID. If the end of the pipe is starin’ right at ya, just put your tape measure or caliper inside and measure across. Easy peasy. But, if the pipe’s all hooked up, and you can’t see the end, that’s a pickle. You can’t really measure the ID then, not without some special tools, or unless you can find another part of the pipe that ain’t hooked up. So, sometimes you just gotta guess, or go by what the pipe is supposed to be. If you know what kinda pipe it is, you might know the ID. They got them standards, you know, for how thick the pipe walls are supposed to be.

And that brings us to the thickness. If you got a caliper, this is where it shines. Just clamp that caliper onto the side of the pipe, and it’ll tell you how thick it is. But if you don’t have a caliper, it’s a bit trickier. You might have to measure the OD and the ID, then subtract the ID from the OD, and then divide that by two. That’ll give you an approximate thickness, if you can measure both the OD and ID. But remember, that galvanized coatin’ can add a bit, so you might need to subtract a little extra for that. How much? Well, it depends. Sometimes it’s just a tiny bit, sometimes it’s a bit more. You kinda gotta eyeball it, or look it up if you know who made the pipe.

Remember, when you’re measurin’ galvanized pipe, you gotta be precise. A little bit off can make a big difference when you’re tryin’ to fit pipes together or connect them to somethin’. And don’t forget to measure in the right spot. If the pipe is bent or damaged, you gotta measure in a good, straight part. Don’t measure where it’s all dinged up, or your measurement won’t be right. And if you’re measurin’ a whole bunch of pipes, measure each one. Don’t just assume they’re all the same. Sometimes they ain’t, even if they’re supposed to be.

So there you have it. That’s how you measure galvanized pipe. Just get yourself the right tools, figure out what you need to measure, and take your time. It ain’t hard, but it’s important to get it right. That way you won’t be runnin’ back to the store, or cussin’ up a storm when things don’t fit.

Key things to remember:

- Choose the right tools: Tape measure, calipers, or pipe measuring tool.

- Measure at the right location: Avoid damaged or bent areas of the pipe.

- Know what you’re measuring: Outside diameter (OD), inside diameter (ID), or thickness.

- Account for the galvanized coating: It adds a little to the thickness.

- Be precise: Accurate measurements are important for a good fit.

That’s about all there is to it. Now you go on and measure them pipes, and don’t you go messin’ it up!