Well, howdy there! Let’s yak a bit about somethin’ called “industrial coil processing.” Don’t you go gettin’ all fidgety, it ain’t as complicated as them city folk make it sound. It’s just about takin’ them big ol’ rolls of metal and makin’ ’em into somethin’ useful. You know, like when you take a big ball of yarn and knit it into a sweater? Kinda like that, but with metal.

What in tarnation is a coil anyway?

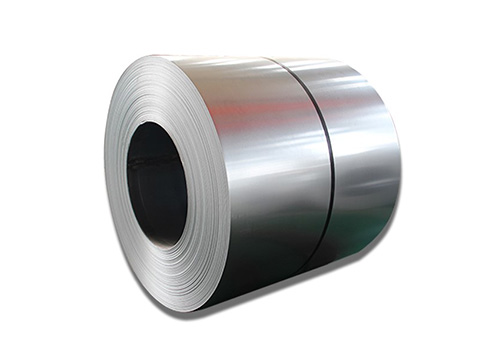

Now, before we get too far ahead, let’s talk about what a “coil” is. Imagine a giant roll of toilet paper, but ‘stead of paper, it’s metal. Yep, that’s pretty much it. Big, heavy, and round. They come in all sorts of sizes, some as big as a tractor tire, some smaller. And they’re made of different kinds of metal too, like steel or aluminum. Steel’s the strong stuff, you know, like what they make bridges outta. Aluminum’s lighter, like what they use for them fancy drink cans.

- Steel coils: Strong and tough, used for buildings and cars.

- Aluminum coils: Light and bendy, used for cans and airplanes.

Makin’ somethin’ outta them coils

So, what do we do with these big metal rolls? Well, that’s where the “processing” part comes in. It’s all about changin’ that big roll into somethin’ we can use. Think of it like cuttin’ up a big ol’ pie. You don’t eat the whole pie at once, do ya? Nah, you cut it into slices. Same thing with the metal coils.

One thing they do is called “slitting.” That’s just a fancy word for cuttin’ the big coil into smaller, skinnier strips. Like if you were cuttin’ a ribbon from a roll. They got these big machines with sharp blades that do the cuttin’. It’s pretty loud, I tell ya, makes a racket like a bunch of chickens squawkin’!

Then there’s “rewinding.” Sometimes, after they slit the coil, they gotta roll it back up nice and neat. Like when you roll up your garden hose after waterin’ the plants. They gotta make sure it’s all tight and even, so it don’t get all tangled up.

Hot-rolled and cold-rolled, what’s the diff?

Now, here’s somethin’ a little tricky. They got different ways of makin’ the metal in the first place. There’s “hot-rolled” steel and “cold-rolled” steel. Hot-rolled is like when you bake a pie real quick at a high heat. It gets the job done, but it ain’t always pretty. Cold-rolled is like bakin’ a pie low and slow. It takes longer, but it comes out smoother and prettier. So, hot-rolled is stronger but rougher, and cold-rolled is smoother but not quite as strong. It just depends on what you need it for, I reckon.

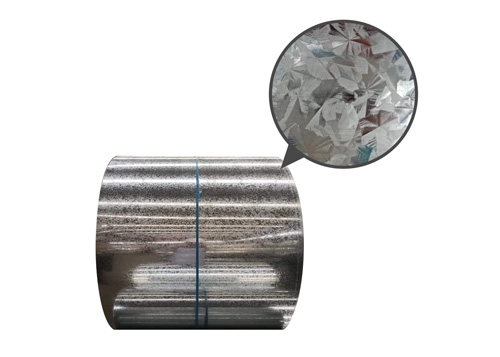

Galvanized coil, rust ain’t gonna get it!

And then there’s somethin’ called “galvanized” coil. That’s when they put a special coat on the metal to keep it from rustin’. Like when you paint your fence to keep it from rottin’. It’s a real lifesaver, ‘specially if you’re gonna use the metal outside where it’s gonna get wet. They use galvanized coil for all sorts of things, roofs, fences, even them big ol’ grain silos you see on farms.

Why do we even need coil processing?

Well, think about it. You can’t just use a giant metal coil the way it is. You gotta cut it, shape it, and make it into somethin’ useful. That’s where coil processing comes in. It’s important for building houses, making cars, and even those tin cans you buy your beans in. It’s like the middleman, takin’ the raw material and gettin’ it ready for the next step. If you see a big roll of that steel layin’ around, you can bet it’s gonna go through some kinda processin’ before it becomes anythin’ useful.

Industrial coil processing is a big deal in a lotta different industries. From construction to manufacturin’, they all rely on it. It’s like the backbone of makin’ things. Without it, we wouldn’t have half the stuff we use every day. So next time you see a metal building or a car, remember those big ol’ coils and all the work that goes into makin’ them into somethin’ useful.

So there you have it, a little bit about industrial coil processing. It ain’t rocket science, just good ol’ fashioned hard work, makin’ somethin’ outta nothin’. Now, if you’ll excuse me, I gotta go make some supper. All this talk about metal and coils got me hungry!

To sum it up:

- Coils are big rolls of metal.

- Processing means cutting, shaping, and getting them ready to use.

- Hot-rolled is strong but rough, cold-rolled is smooth but not as strong.

- Galvanized coil don’t rust.

- Coil processing is important for building stuff and making things.

And that’s about all I know about it. It’s important, real important, I tell ya, for makin’ all sorts of things. Without it, well, things would be a whole lot different, that’s for sure.