You know, when it comes to picking between PPGI and PPGL, folks often get a bit puzzled. They both sound fancy, but really, they’re just different kinds of metal sheets, you see. Now, if you’re wondering which one is better, well, let’s sit down and have a little chat about it, like over a cup of tea, yeah?

First, What Are PPGI and PPGL?

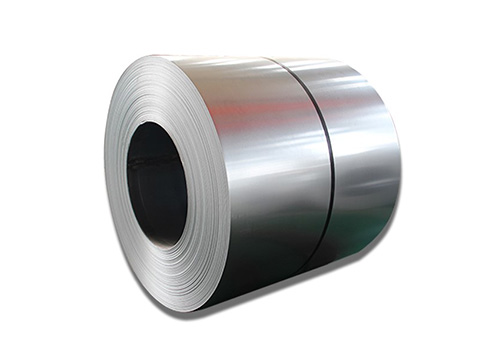

Let’s start simple. PPGI, that’s short for Pre-Painted Galvanized Iron, alright? And then there’s PPGL, which means Pre-Painted Galvalume. Now, these metal sheets are used a lot in construction, roofing, and places where you want something tough to last in the wind and rain. They’re both painted and coated, but the big difference is what’s inside that coating.

What’s the Difference in Coating?

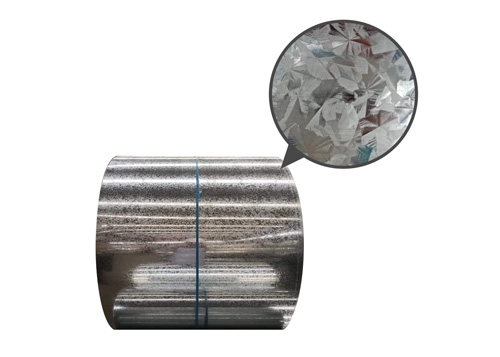

Here’s the thing, PPGI has a zinc coating to keep the rust away. But PPGL, on the other hand, uses a mix called galvalume — that’s mostly aluminum with some zinc and silicon. This galvalume layer does a pretty good job at fighting off the rust too, maybe even a bit better than plain zinc, see? The aluminum in PPGL helps make it last longer and hold up better under tough conditions.

Durability and Lifespan

When you’re putting money into something like this, you want it to last, right? Now, PPGL usually holds up 20 to 30 years, especially in places where the weather’s a bit rough. The aluminum gives it that little extra push against the rust, which means fewer worries about replacements or repairs down the road. PPGI, it’s no slouch either, but it might give you a bit less time in those same conditions because it’s just zinc on there, no aluminum.

Heat Resistance – Here’s Where PPGL Shines

Now, if you’re talking about heat, that’s another place where PPGL pulls ahead. This stuff can handle temperatures up to 315°C. So, if you’re looking at spots with high heat, like maybe a chimney or a pipe in a hot area, PPGL’s gonna be your better choice. PPGI just doesn’t have the same kind of heat strength, so it might not do as well in those hot spots.

Look and Feel – Smooth Finish with PPGL

Funny thing, PPGL has got this nice, smoother finish compared to PPGI. That’s thanks to the aluminum in the galvalume mix, which lets the surface stay smooth and even. Some folks say it’s easier to paint, too, cause you don’t need to do much pre-treating on it. PPGI can sometimes look a bit rougher, which is fine if that doesn’t bother you, but it’s something to think about.

Price Matters

Oh, and we can’t forget about the price. Now, PPGL might sound like the better choice, but it usually costs a bit more than PPGI. So, if you’re on a budget, PPGI might be more up your alley. Sure, it might not last as long or be as smooth, but for folks looking to save, it does the job just fine.

Uses – Where to Use PPGI and PPGL

Now, here’s where it gets interesting. Both PPGI and PPGL can work well for roofing, walls, and even some appliances if they’re painted right. But because PPGL is better with heat and has that smoother finish, it’s a top pick for things like chimneys or pipes in hot areas. PPGI, well, it’s still good for roofs and walls, just maybe not in the hottest places.

Summing It All Up

So, what’s the final word? If you’re looking for something that’s strong, lasts long, and can handle a bit of heat, PPGL might be the better choice. But if budget is tight and you’re okay with replacing it a bit sooner, then PPGI is still a solid option. Both will do the job, but it’s all about what suits your needs best, you know?

So, there you have it – a little rundown on PPGI and PPGL. Both good options, just depends on what you need and how much you’re willing to spend. Remember, sometimes it’s worth spending a bit more to get that longer-lasting finish, but either way, these metal sheets have got you covered!

Tags:[PPGI, PPGL, metal sheets, galvanized iron, galvalume, roofing material, heat resistance, durability]