Now, let’s talk about PPGI and PPGL. These two names might sound fancy, but they’re just kinds of metal sheets, you see. PPGI stands for “pre-painted galvanized iron,” while PPGL means “pre-painted galvalume.” They may sound all complicated, but don’t you worry—I’ll explain it in simple words so even if you’ve never dealt with metal, you’ll understand.

Alright, so first, what’s PPGI? Well, PPGI is just iron or steel that’s been galvanized and painted. Galvanized means they cover it up with a layer of zinc. Why zinc, you ask? Zinc is good at keeping rust away! Just think of it as putting a raincoat on the steel so it doesn’t rust when it rains. Once they’ve got the zinc on it, they go ahead and paint it. Now, this painting is what makes it “pre-painted.” So, in the end, you get a sheet of metal that looks nice and colorful, and it won’t rust easily either.

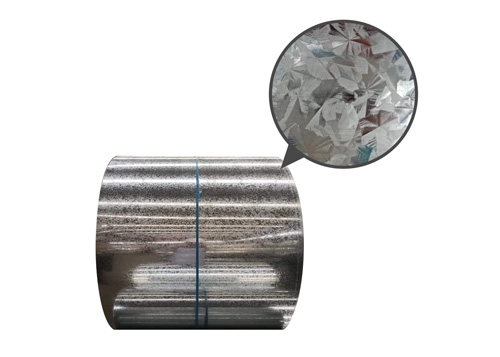

Then we have PPGL, which is almost like PPGI, but with a little twist. Instead of only zinc, they mix aluminum with zinc to coat the steel. So, PPGL stands for “pre-painted galvalume,” and that “galvalume” part means it’s got both zinc and aluminum on it. Adding aluminum makes the metal even stronger against rust. It’s like a double layer of protection, you know? So if PPGI is wearing a raincoat, then PPGL is wearing a raincoat plus an umbrella!

Now, maybe you’re wondering which one is better. It all depends on what you’re using it for. PPGI has a bit more shine and can look smoother, so if you want something pretty and smooth, PPGI might be your pick. It also gives more choices in color and texture, so if you’re picky about looks, that’s a good thing! On the other hand, PPGL is tougher because of the aluminum in there. If you need it to handle harsher weather, then PPGL would be the better choice.

Let’s take a look at some of the main uses of PPGI and PPGL:

- Roofing and siding: Both PPGI and PPGL are popular for making roofs and walls for buildings. They look nice, and they keep out the rain and wind, so they’re great for this kind of job.

- Appliances: You know those fancy colored fridges or washing machines? Yep, sometimes they use PPGI to make the outside because it looks good and holds up well.

- Construction: In construction, these metals come in handy for all kinds of things, from making big industrial sheds to small building panels.

Another thing that’s different about PPGI and PPGL is how long they last. You see, PPGI does well in mild weather but might not hold up as long if it’s out in rough conditions like salty air by the sea. Meanwhile, PPGL, with that aluminum, can handle harsher places better. So, if you’re planning to use it somewhere with heavy rain or salt in the air, PPGL would be a safer bet.

So, when you’re thinking about PPGI and PPGL, just remember:

- PPGI is shiny, smooth, and has zinc coating. It’s best for regular use where you don’t need the extra strength of aluminum.

- PPGL has both zinc and aluminum, so it’s tougher and lasts longer in rough weather conditions.

And one last thing—if you ever need a lot of metal sheets, buying PPGI or PPGL in coils is popular. They sell them in these big rolls, or “coils,” so companies can just unroll and cut however much they need. Saves time and money, and it’s easy to store, too.

So there you have it. PPGI and PPGL may sound like fancy names, but they’re just metal sheets with extra protection. Whether you need a shiny, pretty surface or something that can stand up to rough weather, one of these will do the trick.

Tags:PPGI, PPGL, galvanized steel, galvalume steel, metal roofing, construction materials