Alright, so you wanna know about this PPGL sheet thing, huh? Let me tell ya, it ain’t rocket science. It’s just a fancy name for some kinda metal sheet they use for buildin’ stuff. You know, like them big sheds and roofs and such.

So, what’s the big deal with PPGL?

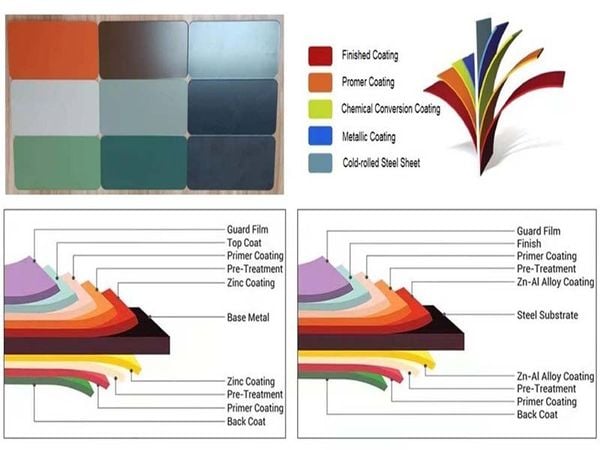

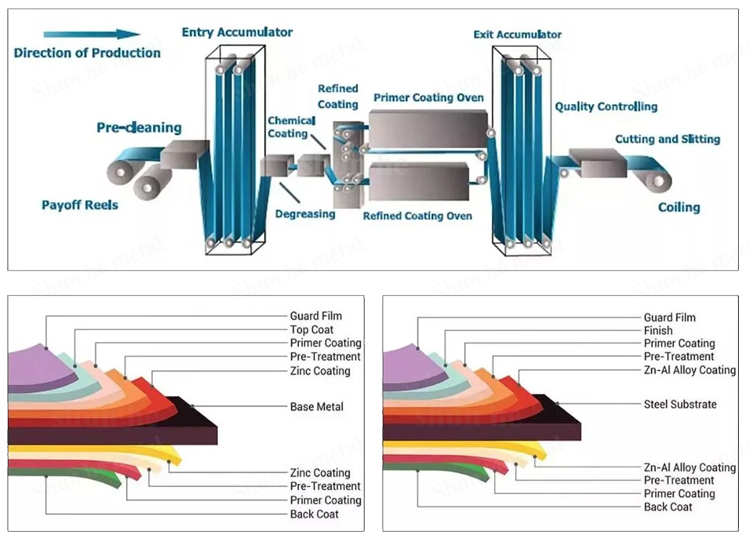

Well, first off, “PPGL” stands for “Pre-Painted Galvalume”. Sounds complicated, but it ain’t. Think of it like this: it’s a metal sheet that’s already painted, so you don’t gotta do it yourself. Handy, right? Saves you a whole lotta trouble.

Now, this Galvalume stuff… that’s the real secret sauce. It’s a mix of metals, mostly aluminum and zinc, with a little bit of silicon thrown in for good measure. Why they mix ’em? Well, it makes the sheet super tough and it don’t rust so easy. That’s important, ya know? Nobody wants a rusty roof over their head.

They melt all them metals together at a real high heat, somethin’ like 600 degrees Celsius. Hotter than my oven gets when I’m bakin’ cookies, that’s for sure. And that heat makes ‘em stick together good and proper. Makes a real strong sheet, this Galvalume does.

- PPGL is tough: It can take a beatin’. Sun, rain, snow… it can handle it all.

- PPGL don’t rust: That Galvalume mix keeps the rust away, makes it last longer.

- PPGL is pretty: Comes in all sorts of colors, so you can pick what you like. No need to paint it yourself, like I said.

Some folks get PPGL mixed up with somethin’ called PPGI. They sound similar, but they ain’t quite the same. PPGI uses just zinc for the coating, not the Galvalume mix. It’s still okay, but PPGL is tougher, lasts longer, specially if you live near the sea where the air is salty. That salt air eats away at stuff, you see.

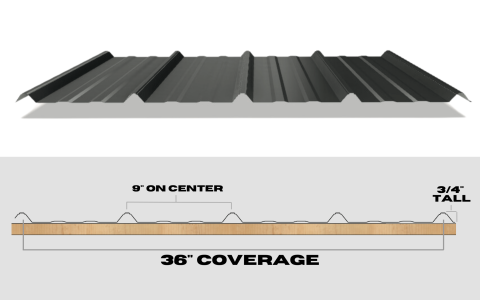

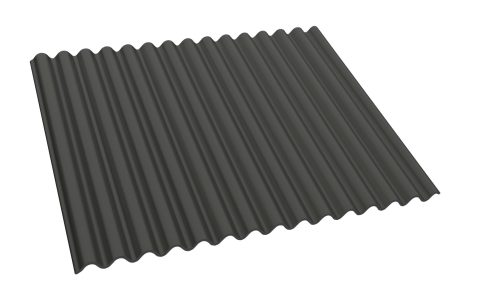

Where do they use this PPGL stuff?

Everywhere, it seems like. Like I said, roofs, sheds, walls… They even use it for them big ol’ warehouses and factories. And you see it in appliances too, like fridges and washing machines. Anything that needs a tough, long-lasting metal, they might use PPGL. It’s just so darn convenient, ya know?

So, why’s PPGL so popular these days?

Well, it’s tough, it don’t rust, and it’s already painted. What’s not to like? It saves builders time and money, and it gives you a roof or a wall that’s gonna last a good long while. Nobody wants to be fixin’ stuff all the time, right? You wanna put it up and forget about it, and PPGL lets you do just that.

Now, if you go and cut a PPGL sheet, you gotta be careful. The cut edge ain’t got that Galvalume protection no more, so it might rust if you don’t seal it up. They got special paints and stuff for that, gotta make sure you use it. Otherwise, all that rust-proofin’ was for nothin’.

What’s PPGL made of, exactly?

Like I said before, it’s mostly aluminum and zinc. But to be precise, it’s somethin’ like 55% aluminum, 43.4% zinc, and 1.6% silicon. Don’t ask me why them numbers exactly, some scientist fella figured that out. All I know is that it works, makes the sheet strong and keeps the rust away. That’s all that matters to me, and I reckon it’s all that matters to most folks too.

PPGI versus PPGL, what’s the difference again?

Remember, PPGI, it just got zinc, like a plain ol’ galvanized sheet, but with a paint job. PPGL is the fancy one, with the aluminum and all. Think of PPGI like a regular ol’ car, and PPGL like a truck. Both get you where you need to go, but the truck is tougher and can handle more. That’s a good way to think about it.

In short, PPGL sheet meaning…

It means you got a strong, long-lasting metal sheet that’s already painted and ready to go. It means you don’t gotta worry about rust, and it means you got somethin’ that’s gonna last a good long time. Simple as that. Now, go on and build somethin’ nice, ya hear?