| Thickness: | 0.2mm – 3mm |

| Width: | 40-1650mm |

| Alloy: | 1050/1060/1100/1200/3003/3004/3005/3104/3105/5052/5754/5005/5182 |

| Length: | Customers’ Requirement |

| Coated: | PE,SMP,HDP,PVDFCoated |

| Coil Weight: | 1.5-4 Tons or as requirment |

| Temper: | O – H112 |

| Standard: | ASTM,EN,GB |

| Certification: | ISO9001,SGS,KEBS |

| Package: | Export standard packing or according to customers’ requirement. |

| MOQ: | 7 Tons |

| Delivery Time: | Normally within 10-25 working days |

| Painted Brand: | AKZONOBEL,Nippon Paint,PPG,VALSPAR,KCC,etc |

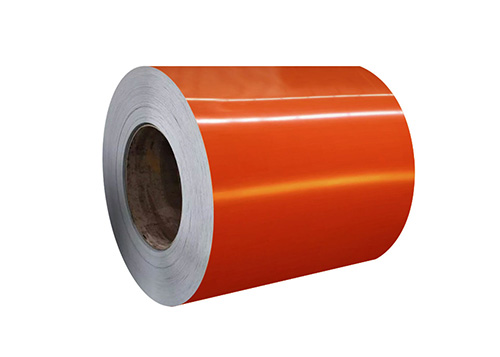

Prepainted Aluminum Coil (PPAL) & Aluminum Coil: The Perfect Blend of Aesthetics, Durability, and Versatility

In the competitive world of metal materials, Prepainted Aluminum Coil (PPAL) and Aluminum Coil stand out for their blend of lightweight strength, corrosion resistance, and customizable appearance. These aluminum products are increasingly preferred in industries ranging from construction and automotive manufacturing to appliance design, where the combination of durability and aesthetic appeal is essential. This article explores the unique properties, advantages, and applications of PPAL and aluminum coils, providing a comprehensive look at why these materials are essential in modern design and engineering.

What are Aluminum Coil and Prepainted Aluminum Coil (PPAL)?

An aluminum coil is a rolled aluminum sheet that is easy to work with, lightweight, and known for its high corrosion resistance. Aluminum itself is a popular material due to its low density, which makes it lightweight yet strong. Additionally, aluminum coils are highly malleable, allowing them to be cut, shaped, or welded to meet a variety of specifications.

Prepainted Aluminum Coil (PPAL) takes the benefits of plain aluminum coils to the next level by applying a layer of paint. The aluminum coil is first treated with a surface coating that enhances its corrosion resistance, and then coated with a layer of high-quality paint that not only protects but also adds aesthetic appeal. This process gives PPAL an attractive, long-lasting finish that resists fading, chipping, and corrosion, making it an ideal choice for decorative and functional applications.

Benefits of Aluminum Coils and PPAL

1. Excellent Corrosion Resistance

One of the biggest advantages of both aluminum coils and PPAL is their natural resistance to corrosion. Aluminum forms a protective oxide layer when exposed to air, which shields it from rust. PPAL coils go a step further by adding a high-quality paint coating, creating an even more resilient surface that can withstand harsh weather, pollutants, and UV rays.

2. Lightweight and Durable

Aluminum is known for being lightweight, which reduces transportation and installation costs. Despite its lightness, aluminum is extremely strong, offering a high strength-to-weight ratio that is perfect for applications requiring durability without added weight. PPAL retains this lightweight quality, while the additional paint layer enhances its scratch and impact resistance.

3. Versatile Aesthetic Options

PPAL offers endless design possibilities due to its wide range of color options and finishes. From matte and glossy finishes to textured and metallic effects, PPAL allows designers and builders to incorporate visually appealing elements into structures and products. This makes PPAL particularly popular in applications where appearance matters, such as roofing, facades, and interior decor.

4. Heat Reflectivity

Aluminum’s natural reflectivity makes it ideal for applications where heat management is important. In hot climates, aluminum can reflect up to 95% of solar radiation, reducing the heat absorbed by buildings and helping maintain cooler indoor temperatures. This property is especially beneficial in roofing and cladding, where reflective PPAL panels contribute to energy efficiency.

5. Easy Fabrication and Maintenance

Aluminum is easy to shape, cut, and weld, allowing it to be adapted to various designs and specifications. PPAL, with its painted coating, is equally workable and maintains its appearance over time with minimal upkeep. This makes both aluminum coils and PPAL easy to clean and maintain, further enhancing their longevity.

Applications of Aluminum Coils and Prepainted Aluminum Coil

1. Construction Industry

In construction, aluminum coils and PPAL are commonly used for roofing, wall cladding, ceilings, and facades. The durability and corrosion resistance of aluminum make it an ideal material for structures exposed to the elements. PPAL, with its diverse color options, provides builders and architects with the flexibility to create visually appealing and resilient structures.

PPAL coils are often selected for high-rise buildings, commercial complexes, and residential projects, especially in locations prone to extreme weather. With their lightweight nature, PPAL panels reduce the load on buildings, making them a smart choice for both new constructions and renovations.

2. Automotive Industry

Aluminum’s lightweight properties contribute to fuel efficiency and reduced emissions in vehicles. In the automotive sector, aluminum coils are often used in body panels, heat shields, and undercarriage components. PPAL’s attractive finish also allows manufacturers to add stylish, corrosion-resistant components to car interiors and exteriors.

3. Appliances and Consumer Goods

For appliances like refrigerators, washing machines, and microwaves, aluminum coils provide a lightweight, corrosion-resistant option that’s easy to work with. PPAL brings an added aesthetic advantage, allowing manufacturers to produce colorful, scratch-resistant, and stylish consumer goods. This aesthetic flexibility allows appliance manufacturers to cater to a variety of design preferences, which is increasingly important in competitive markets.

4. Signage and Advertising

PPAL’s vibrant color options and weather resistance make it a popular choice for outdoor signage, advertising billboards, and displays. The durable painted surface of PPAL resists fading, even with prolonged exposure to sunlight and rain, making it perfect for long-term outdoor advertising. Aluminum’s easy-to-handle properties also make it simple to cut and mold into intricate designs, enhancing the quality of signage.

5. Electrical and Electronic Industry

Aluminum is widely used in the electrical industry due to its conductivity and lightweight nature. Aluminum coils are often used in heat exchangers, cooling systems, and cable shielding. PPAL is also popular in electronics casings, providing a durable, protective, and aesthetically pleasing surface for a variety of devices.

Key Considerations When Choosing Aluminum Coils or PPAL

1. Coating Type and Thickness

In PPAL, the type and thickness of the paint coating significantly impact the durability and performance of the coil. Thicker coatings typically offer better protection but may add to the cost. Ensure the coating matches the application requirements, particularly for projects involving outdoor exposure.

2. Color and Finish Options

Since PPAL is available in a broad spectrum of colors and finishes, selecting the right combination is important for achieving the desired look and functionality. While matte finishes are suitable for a subtle look, glossy or metallic finishes can make a structure or product stand out. Texture options are also available, which can add depth and a more premium appearance.

3. Environmental Conditions

When selecting aluminum coils or PPAL, consider environmental factors like temperature, humidity, and sunlight. Coastal or industrial areas may require enhanced corrosion resistance, making PPAL with thicker coatings a better option. Additionally, reflective coatings are ideal for applications exposed to high levels of sunlight.

4. Supplier Quality and Certification

Choosing a reliable supplier that meets quality standards like ISO ensures the aluminum coil or PPAL meets performance expectations. Certified suppliers adhere to industry standards, providing assurance of the material’s durability, appearance, and safety.