|

Thickness: |

0.13mm-2.0mm |

|

Width: |

40-1250mm |

|

Zinc Coating: |

Z30-275g/m2 |

|

Coated: |

PE,SMP,HDP,PVDFCoated |

|

Painted Brand: |

AKZONOBEL,Nippon Paint,PPG,VALSPAR,KCC,etc |

|

Hardness: |

Soft,CQ,full hard |

|

Surface |

Matt/Wrinkle,Sand,High gloss,design, |

|

Length: |

Customers’ Requirement |

|

Coil Weight: |

3-5 Tons or as requirment |

|

Color: |

RAL color |

|

Certification: |

ISO9001,SGS,KEBS |

|

Package: |

Export standard packing or according to customers’ requirement. |

|

MOQ: |

27Ton |

|

Delivery Detail |

Within 3-15 days after receipt of deposited |

|

Supply Ability |

30000Tons per Month |

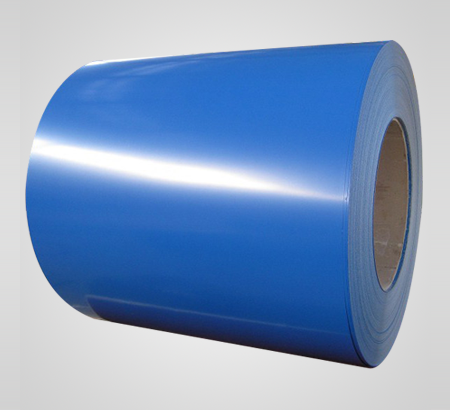

Prepainted Galvanized Steel Coil (PPGI): The Premium Solution for Color, Durability, and Versatility

In the world of steel products, Prepainted Galvanized Steel Coils (PPGI) are highly regarded for their versatility, corrosion resistance, and aesthetic appeal. PPGI coils are steel sheets coated with a layer of zinc for protection and then painted, offering a combination of durability and attractive appearance that makes them an ideal choice for a range of industries, from construction to automotive manufacturing. This article will explore the benefits, applications, and key considerations when selecting PPGI steel, showing why it has become a staple in modern design and construction.

What is Prepainted Galvanized Steel Coil (PPGI)?

Prepainted Galvanized Steel Coil, or PPGI, begins with a base of galvanized steel, which is coated in zinc to create a corrosion-resistant layer. After galvanization, the steel undergoes a pre-painting process where a layer of paint is applied using high-quality coatings that adhere to the steel surface. This multi-step process includes surface treatment, base coating, and top coating, which add further durability, color, and protection, making PPGI coils resistant to rust, fading, and harsh weather conditions.

PPGI coils are available in a variety of colors, textures, and finishes, allowing designers and builders to select products that meet both functional and aesthetic needs. From sleek modern facades to vibrant roofs, PPGI is a practical yet eye-catching solution for a variety of projects.

Advantages of Using PPGI Coils

1. Superior Corrosion Resistance

The primary advantage of PPGI is its exceptional corrosion resistance. The galvanized zinc layer provides a strong base protection against rust, while the top paint layer further shields the steel from harsh environmental factors such as rain, sun exposure, and pollutants. This double layer of protection means that PPGI can maintain its durability and appearance over long periods, making it suitable for both outdoor and indoor applications.

2. Enhanced Aesthetic Appeal

PPGI coils are available in a wide range of colors and finishes, including gloss, matte, and textured surfaces. This versatility allows architects and designers to create visually appealing structures and products, adding a polished, professional touch to projects. Unlike traditional galvanized steel, PPGI provides color consistency and quality that make it ideal for any design-forward application.

3. High Strength and Lightweight

Despite being lightweight, PPGI steel is highly durable, making it easier to transport, handle, and install without compromising structural integrity. The combination of zinc and painted coatings also strengthens the coil, adding extra protection against scratches, dents, and impacts. This makes PPGI an excellent choice for building structures that need both resilience and weight efficiency.

4. Easy to Process and Form

PPGI coils are highly workable and can be cut, shaped, and formed to fit a wide range of specifications. The coatings used in PPGI also make it easier to weld, press, and mold, making the material suitable for various manufacturing processes. This adaptability allows PPGI to be used in a range of products, from roofing sheets to appliances.

5. Cost-Effective and Long-Lasting

Though the initial cost of PPGI may be higher than uncoated or simple galvanized steel, its long lifespan and minimal maintenance requirements make it cost-effective in the long term. PPGI is resistant to fading, rust, and wear, reducing the need for frequent replacements or touch-ups, especially in environments exposed to extreme weather conditions.

Key Applications of PPGI Steel Coils

1. Construction Industry

The construction industry relies heavily on PPGI coils due to their durability, appearance, and low maintenance requirements. Common uses include roofing, cladding, and wall panels for both residential and commercial buildings. Because PPGI comes in a variety of colors, it allows for seamless integration into diverse architectural designs while offering long-lasting protection against environmental factors.

2. Automotive Manufacturing

In the automotive industry, PPGI is commonly used for producing body panels, fenders, and interior components. Its corrosion resistance, coupled with the attractive finish, makes it a popular choice in vehicle manufacturing. PPGI-coated components not only enhance the vehicle’s appearance but also extend its lifespan by protecting against rust and wear, particularly in areas prone to moisture and road salt exposure.

3. Appliances and Consumer Goods

PPGI steel is also widely used in the production of household appliances such as refrigerators, washing machines, and microwave ovens. Its resistance to scratches, heat, and chemicals, along with its aesthetic appeal, make it ideal for products that need to look good while withstanding regular use. The custom color options available also help manufacturers align with branding needs and design trends.

4. Agricultural Equipment and Structures

Agricultural applications require materials that can withstand harsh outdoor conditions, and PPGI steel is often used for building sheds, barns, and grain storage facilities. The corrosion resistance provided by the zinc and paint layers ensures that PPGI-based structures can endure exposure to humidity, rain, and varying temperatures, making it a reliable choice for agricultural needs.

5. Furniture and Interior Decor

In addition to heavy-duty applications, PPGI coils are used in producing decorative items and furniture. Tables, cabinets, and shelves made from PPGI are sturdy, visually appealing, and easy to clean, making them popular for both residential and commercial spaces. PPGI’s durability and array of finishes allow for stylish yet practical interior design.

Key Considerations When Choosing PPGI Coils

1. Coating Type and Thickness

The type of paint coating and its thickness play a significant role in determining the durability and suitability of PPGI for specific applications. Thicker coatings provide better protection but may add to the cost. It’s essential to assess the environment in which the PPGI will be used and select a coating thickness accordingly.

2. Color and Finish

Different projects require different visual aesthetics, so selecting the right color and finish is essential. PPGI coils come in a variety of hues and textures, from glossy and matte to woodgrain and marble finishes. Choosing the correct color and finish can greatly impact the appearance of the final product or structure.

3. Quality Standards and Certification

Choosing a reputable supplier that adheres to industry standards, such as ISO or ASTM, ensures that the PPGI coils meet necessary quality and safety requirements. Certified materials also come with guaranteed performance, which is critical for structural applications.

4. Environmental and Usage Conditions

It’s important to consider environmental factors like humidity, salt exposure, and temperature when selecting PPGI. Harsh environments may require thicker coatings and specific paint types to ensure longevity and performance.