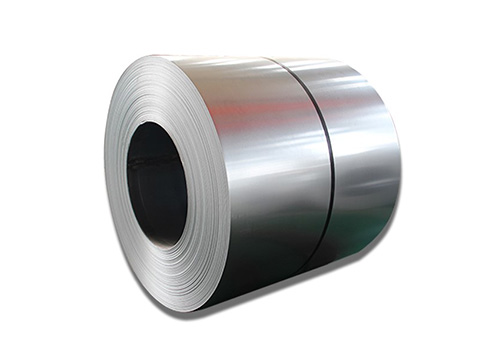

Sheet Metal Coil, it sounds impressive, but it is actually a whole roll of iron sheet rolled up, it is a “roll”! This thing is really very useful.

Speaking of sheet metal coil, it is actually steel, aluminum and other metal materials, stretched and flattened, made into thin sheets, and then rolled into a large cylinder. This kind of roll is different from the iron sheet we lay. This kind of roll must have a certain thickness and width to be rolled. It looks big and heavy, and it is like a big plate when rolled up.

Sheet metal coils can be used in many places, such as building houses, warehouses, and cars. In fact, the most common metal coils are steel coils and aluminum coils. These two materials are indispensable materials for building houses at home!

What is the difference between steel coils and aluminum coils?

Alas, some people don’t understand and can’t tell what sheet metal coils are made of. In fact, to put it bluntly, steel coils are heavier than aluminum coils, but cheaper; aluminum coils are lighter, but more expensive. If we want to cover the roof with iron sheets, steel coils are stronger. Steel coils are pressure-resistant and durable, and the price is affordable.

Aluminum coils are lighter and have good anti-rust effects. This thing is most suitable for use in places with heavy humidity, such as coastal areas. Aluminum coils for roofs will not rust. Of course, they are also suitable for making some light small items.

The thickness of Sheet Metal Coil is particular

This thing is very particular about thickness. Steel coils are thin and thick. The big iron shed at the entrance of our village uses thick coils, which can be compacted and then rolled up. Coiled materials usually have three thicknesses. The thickest is called plate, the medium thickness is sheet, and the thinnest is called coil, which is a long and thin metal coil.

Thick plates are steel plates for construction, which can be used for foundations, especially bridges and roads. Thin coils can only be laid on roofs or used in light projects, and are cheaper.

How to measure the weight and length of Sheet Metal Coil?

When this thing is rolled up, the thickness and diameter must be calculated. If it is too thin, it cannot bear it, and if it is too thick, it cannot be rolled up! If you want to measure it, there are several ways, generally looking at the inner diameter, outer diameter and width of the coil.

For example, if you want to know how heavy and long this roll of metal sheet is, you have to use a calculator. Now people have ready-made coil calculators to calculate weight and length. Enter the thickness, width and diameter, and you can calculate it directly.

In addition, coil calculators can also help you estimate the weight. Those calculation tools can calculate the weight of the entire roll based on the width and inner and outer diameters of the coil, so you don’t have to measure it one by one, which is very convenient.

Processing methods of Sheet Metal Coil

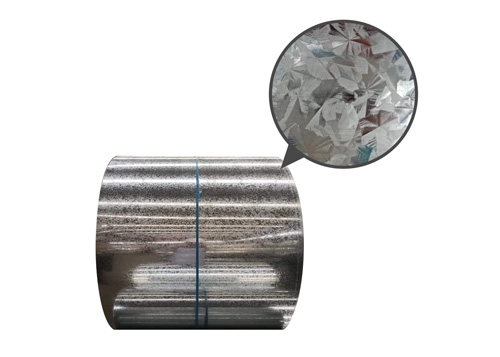

This coil can also be processed according to needs. Usually, there are two methods: hot rolling and cold rolling. Hot rolling is to heat the steel and then press it into a coil. That is the work of large machines, and several coils can be produced at a time. Cold rolling is to press at room temperature, and the surface of the steel produced is very smooth, which is suitable for use in more delicate places.

There are more ways to process coils. Coils can also be cut into various shapes, such as cutting coils into small pieces, which is convenient for transportation and processing. Used in car manufacturing, it is first cut into the required size, then welded or polished, and finally assembled to make the finished product!

Uses of Sheet Metal Coil

The uses of this coil are very wide! Usually used at home, such as the roof of a tin house or warehouse. For larger ones, the roof of a factory building is also supported by these coils. If it is broken, just repair it, which saves trouble, money and time, and is not afraid of wind.

Another thing is that high-rise buildings in big cities, as well as large sheds at railway stations and bus stations, are all made of coils. With coils, houses are built quickly and there is no fear of leaks. Roadside fences and billboard brackets in cities are also processed and formed with this metal coil.

Sheet metal coil is also used in cars and machines to make shells, parts, etc. It is light and durable. Just like a coil, it can be cut and folded, and can be made into any shape you want. This thing is really strong!

Summary

Sheet metal coil, whether it is steel or aluminum, is a practical thing. It is stretched, flattened, and rolled into a roll, suitable for various projects. Thin coils are light and suitable for small places. Thick coils are stronger and are perfect for roofs, exterior walls, and protective panels. If you want to calculate weight and length, there is a calculator, and then cut the rolls into small rolls for easy use.

In short, sheet metal coil is a good material that is indispensable for various large projects, buildings, cars and machinery. Whether it is small or large, it can always be used. Convenient and durable, that is really the excellent advantage of “metal coil”!

Tags:[sheet metal coil, steel coil, aluminium coil, coil thickness, coil uses, metal coil weight calculation]