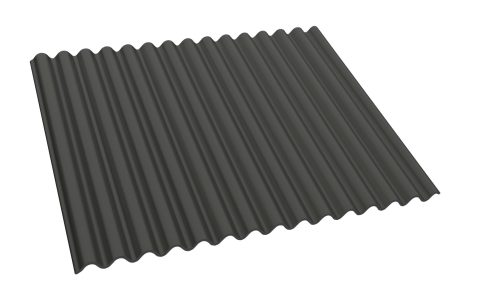

Well, let me tell you about this cold rolled steel coils thing. You see, it’s like when you take a piece of dough, roll it out, and then roll it some more to make it all nice and thin. That’s what they do with steel, too! They take hot rolled steel, which is already kind of thick, and then they do some extra work on it to make it just right.

Now, this cold rolling, it’s not just for fun. Nope! It’s all about getting the steel to be the right size and smooth as a baby’s bottom. After the hot rolled steel cools down, they roll it again when it’s nice and chilly. This makes the steel thinner and gives it a better finish. It’s like polishing your shoes until they shine!

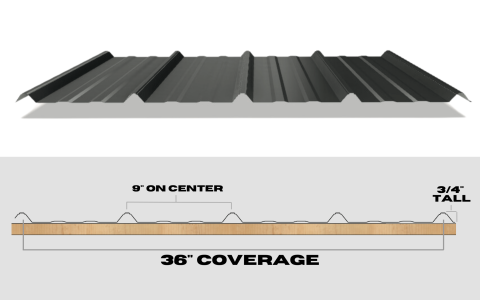

Cold rolled steel coils are super handy. You can use them where you need things to fit just right and look good. You know, like when you want a new gate for the yard, or maybe some shelves in the barn. It’s important that these things are strong but also fit together well. Otherwise, everything’s all crooked and looks bad.

- Thickness Tolerance: This means they can make the steel super thin, just like you want it!

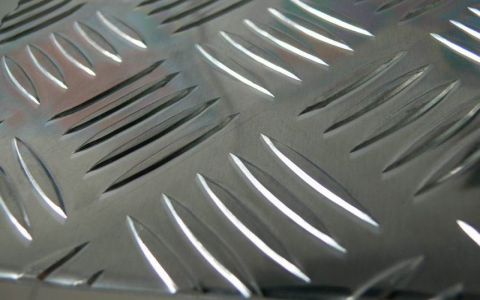

- Surface Condition: The surface is all smooth and pretty, perfect for painting or whatever else you need.

And let me tell you, this cold rolled stuff can come in all kinds of finishes. Some are shiny, and some are more like the rough old tools we use around the house. Depending on what you need, you can pick the right one. It’s just like picking apples—some are red, some are green, and you gotta know which one you want!

Now, the process to make these coils isn’t just something you can do in your backyard. Oh no, it takes special machines and a lot of know-how. First, they take those hot rolled coils and send them through a mill. The mill squishes them down to the right size, and then they go through a bunch of other steps to make sure they’re perfect.

They also do something called annealing, which sounds fancy but just means they heat the steel up and then cool it down again. This helps to make it stronger. Then they pickle it—no, not the kind you eat! It’s a cleaning process that makes sure all the gunk is off the steel. Just like when you wash your vegetables before cooking!

Once that’s all done, they roll it out again and get it ready to ship off to whoever needs it. You can find these coils used in all sorts of things, from cars to buildings to all the metal bits in between. It’s amazing how something so simple can be used for so many things!

So, if you ever hear someone talking about cold rolled steel coils, just remember it’s a special kind of steel that’s been worked over real good. It’s strong, it’s pretty, and it’s just right for lots of jobs. Just like how Grandma makes the best pies—she puts in the effort, and you can taste it!

Tags:[cold rolled steel, steel coils, thickness tolerance, surface condition, annealing, metal processing]