Now, listen here, I ain’t no steel expert, but I do know a thing or two ’bout what this ASTM A1011 business is all about. It’s a fancy name for a kind of steel, you see. A good, sturdy kind of steel used in all sorts of places, like in buildings, cars, and even some of them big machines folks use on farms. This here steel, the A1011, it’s what they call “hot-rolled,” which just means they get it real hot and then roll it out flat, real smooth like. Makes it stronger, you know.

This A1011 steel comes in different types too. They got what they call “carbon steel,” “structural steel,” and some of it’s got a little extra strength in it too, what they call “high-strength low-alloy steel.” Now, don’t get all confused by them big words, it just means they mix a little bit of other metals in there to make it tougher and more durable, especially when it needs to hold up under a lot of pressure or weight.

So, why do folks use this A1011 steel? Well, it’s real good for things that need to be strong but still kinda light. You see, it’s not the heaviest steel out there, but it sure gets the job done. That’s why they use it for making parts for cars, trucks, and even stuff like bridge beams. You know, those big pieces that hold up the bridges so we can drive across ‘em without worryin’ they might collapse. Also, it’s used in things like machine parts or even in the construction of buildings. Strong and reliable, that’s what this steel is.

Now, this steel ain’t just one thing. There’s a whole bunch of different grades of it. Some are stronger, some are more flexible, and some are just real good for basic stuff. There’s what they call “CS,” which stands for carbon steel, and then there’s “SS,” which means structural steel. And then, you got your “HSLAS” – that’s the high-strength low-alloy kind. They even got different grades within those categories, so folks can pick the one that’s right for what they need.

- Carbon Steel (CS): This is the most basic kind. It’s cheap and it gets the job done, but it’s not as strong as some of the other kinds.

- Structural Steel (SS): This kind’s used in buildings and heavy machinery. It’s tough and made to hold up under a lot of weight.

- High-Strength Low-Alloy Steel (HSLAS): This one’s stronger than regular carbon steel and more resistant to wear and tear. It’s good for when you need something real tough, like in heavy-duty construction or big equipment.

Now, if you’re wonderin’ what’s so special about this A1011 steel compared to other kinds of steel, well, it’s mostly about how they make it. They heat it up, roll it, and then cool it down just right. That process helps keep it from bein’ too brittle. It doesn’t break easily like some other kinds of steel, and it’s pretty good at withstanding pressure. But don’t go thinkin’ it’s invincible – it’s still steel, after all, and anything’s got its limits.

What about the mechanical properties of this steel? Well, A1011 has a good balance between strength and flexibility. That means it’s tough enough to be used in heavy-duty stuff, but it still bends without snapping when it needs to. If you look at the strength, you’ll find that it’s got a minimum tensile strength of around 50,000 PSI (that’s pounds per square inch for those who ain’t familiar). So it’s pretty strong, but not as strong as some of the special, high-strength steels out there.

And as for the chemical makeup of the A1011 steel, well, it’s got a good bit of carbon in it, which helps make it strong. It also has a little bit of manganese and some other elements like phosphorus and sulfur, which are there to improve how it works in different conditions. You don’t need to know all the details, but just know that they mix those ingredients to make sure the steel doesn’t rust or break too easily, even in tough environments.

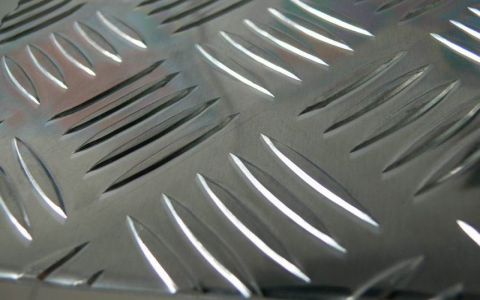

Some folks might wonder if this A1011 steel can be welded or formed into different shapes. The answer is yes! It’s got decent formability, so you can weld it together or bend it without too much trouble. That’s part of what makes it so useful for all sorts of applications. Whether it’s makin’ car parts or putting together parts of a building, this steel can be worked with in many different ways.

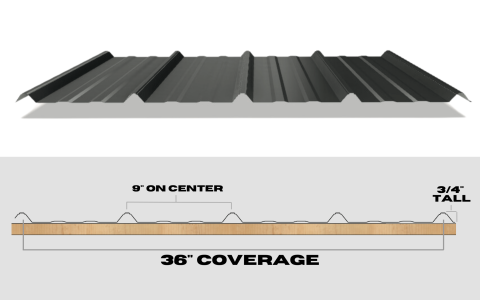

But what about the thickness and size of this steel? Well, A1011 comes in sheets and strips, and they can be as thick as you need ’em to be. Some of them are real thin – for things like automotive parts – and others are much thicker for more heavy-duty applications. The thickness and width of the steel are all laid out in the standards, so folks know exactly what they’re getting when they order it. And if you need it in coils or cut into specific lengths, you can get that too.

All in all, this ASTM A1011 steel is a pretty versatile and reliable material. Folks all over use it because it’s tough, not too heavy, and it can be used in so many different ways. Whether it’s for building roads, bridges, cars, or machines, this steel gets the job done, and it don’t cost too much either. So, if you ever need some steel that can hold up under pressure, you might just want to give A1011 a look.

Tags:[ASTM A1011, hot-rolled steel, carbon steel, structural steel, high-strength low-alloy steel, HSLAS, steel properties, mechanical properties, steel grades, building materials]