Alright, now, let me tell you about PPGI and PPGL. This is somethin’ folks in construction like, but anyone who knows a bit about steel and metals might come across it too. Now, PPGI, that stands for Pre-painted Galvanized Steel, while PPGL is Pre-painted Galvalume Steel. They both get pre-painted, but don’t be fooled, there’s a couple important differences that set ’em apart.

Now, PPGI, this type of steel’s got a zinc coating all over it, like coverin’ it head to toe. This zinc layer is good ‘cause it helps the steel not rust so fast. Rust can just eat away at metals, but zinc is like a shield, keepin’ it lookin’ nice for longer. PPGL though, it’s got a different type of coating on it. PPGL has a mix of aluminum and zinc instead of just zinc. Now, that little bit of aluminum in there, it adds some extra power to resist the weather. Folks in rainy areas, or places with all sorts of bad weather, often go for PPGL because that aluminum can keep the metal strong and lookin’ fresh longer.

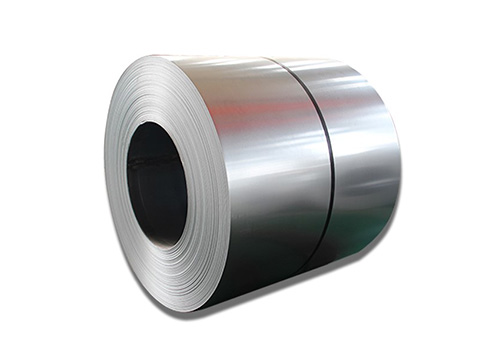

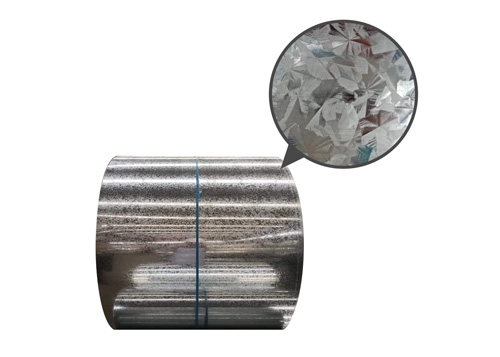

Now, one of the big differences here is the way PPGI and PPGL look. If you’re lookin’ at ‘em side by side, you might notice PPGI’s got a real shiny, smooth look. Makes it kinda eye-catching. PPGL, on the other hand, doesn’t shine as much. It’s got a bit of a rougher finish, which some folks actually prefer. In some cases, that little roughness makes it blend in better with certain designs. So, dependin’ on what look you’re after, you might go with one or the other.

When it comes to customizin’ the colors and patterns on these two, PPGI tends to have the upper hand. It’s easier to paint and get exactly how folks want it. So if someone wants a very specific look, say like some fancy color for a new building or factory, PPGI is often the choice. But that doesn’t mean PPGL isn’t useful, it’s just got a bit less room for fancy customizations.

Now, let’s talk about where folks use PPGI and PPGL. Both of these are real popular in construction and manufacturing. You’ll see ‘em on roofs, walls, even some machines and appliances. Sometimes folks use PPGI and PPGL in fences and gates too because they both handle weather pretty well. But remember, if it’s in a place where it rains a lot or has heavy snow, PPGL might hold up better since it’s got that mix of aluminum and zinc protecting it.

- PPGI (Pre-painted Galvanized Steel): Full zinc coating, shiny finish, good for custom colors.

- PPGL (Pre-painted Galvalume Steel): Aluminum and zinc coating, tougher in harsh weather, less shiny.

So, in short, if ya need somethin’ that looks nice and shiny, maybe a particular color, and it’s not in a place with rough weather, PPGI might be the right pick. But, if it’s somethin’ that needs to stay strong against all kinds of weather, then PPGL could be better for the job. Ain’t no big secret, just dependin’ on where you’re plannin’ to use it and what look you’re goin’ for.

Now, I hope this helps ya understand a bit more about these two types of steel. They might seem like small details, but when it comes to buildin’ somethin’ that’ll last, pickin’ the right one can make all the difference.

Tags:PPGI, PPGL, pre-painted galvanized steel, pre-painted galvalume steel, construction materials, roofing, steel coils