Alright, let’s talk about this galvanized coating thing, you know, that shiny stuff on metal. I ain’t no fancy engineer, but I know a thing or two about stuff that lasts, and that coating, well, it matters how thick it is.

You see, thicker ain’t always better, but too thin, and it’s like wearin’ a flimsy shirt in a hailstorm, won’t do ya no good. So, what makes that coating thick or thin? Well, it’s a whole bunch of things, like a recipe, gotta get it all just right.

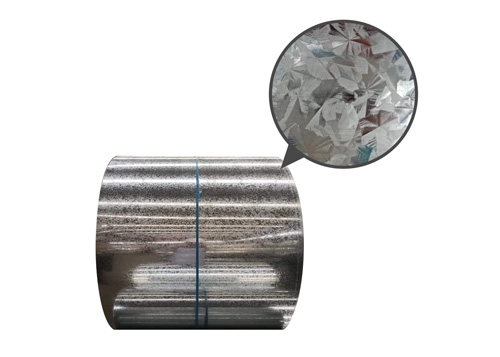

- First off, they gotta clean that metal real good. Like, scrubbin’ pots and pans after a big supper, but way more serious. If they don’t, the coating won’t stick right, and you end up with a thin, patchy mess. They call it “grit blasting” sometimes, sounds fancy, but it’s just makin’ the metal rough so the coating can grab on. Think of it like scratchin’ up the dirt before plantin’ seeds, gotta give ’em somethin’ to hold onto.

- Then, there’s the metal itself. Thicker pieces of metal, they tend to get a thicker coat. Makes sense, right? Bigger the thing, the more stuff it needs to cover it up. And it ain’t just the size, but what’s in the metal too. They got all these fancy names for the stuff, but basically, some metals just take the coating better than others. It’s like how some folks tan easy and some get burnt to a crisp, just depends on what you’re made of.

Now, this whole galvanizing thing, it ain’t magic, though sometimes it seems like it. They dip that metal in hot melted stuff, zinc they call it, and that’s what makes the coating. How long they leave it in, how hot it is, that all matters. Too short, too cold, you get a thin coat. Too long, too hot, well, you might get a thick coat, but it might not be so smooth, and that can cause problems too.

And don’t you go forgettin’ about the welding. You know, when they stick two pieces of metal together? If they ain’t careful, that weld can mess up the coating. They gotta clean it up good, otherwise, you get lumps and bumps and the coating won’t be even. It’s like tryin’ to frost a cake that’s got crumbs all over it, just ain’t gonna look right.

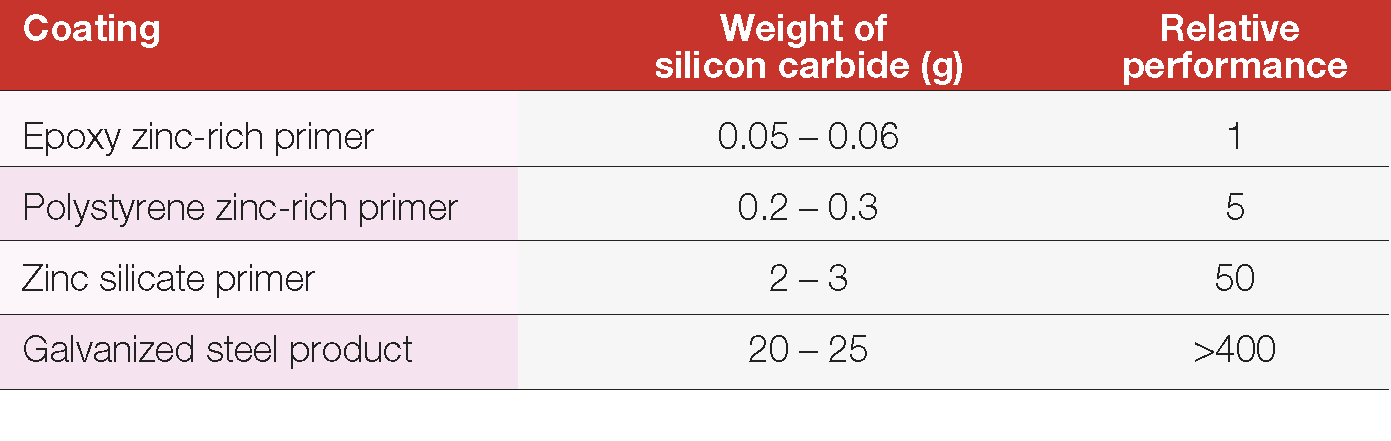

So, how do you know if the coating is thick enough? Well, they got ways of measuring it, fancy machines and stuff. But mostly, you just gotta look at it. A good thick coating, it’ll be smooth and even, no bare spots, no drips, no nothin’. And it’ll last, that’s the important part. You don’t want your metal rustin’ away on ya, do ya? That’s why that coating thickness matters. It’s like a good pair of boots, gotta be strong enough to handle whatever you throw at it. And just like them boots, a good thick coating will protect your metal for years to come.

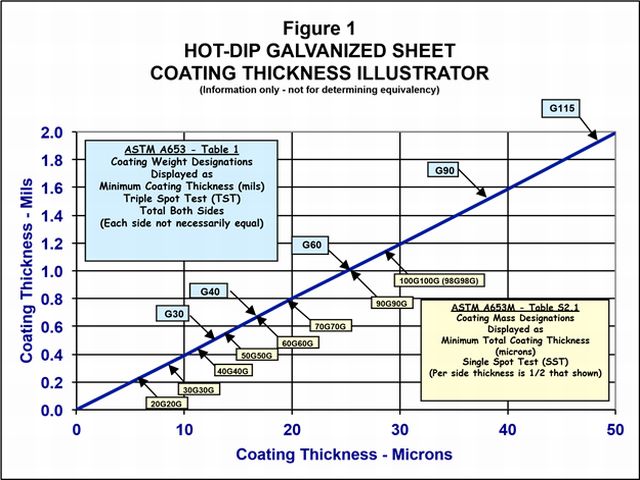

Sometimes they talk about the coating weight, how much it weighs, instead of how thick it is. But it’s kinda the same thing, you know? More weight means a thicker coat mostly. They use fancy scales and stuff, more precise than my old kitchen scale, that’s for sure.

So, there you have it. A whole lot of things go into making that galvanized coating just right. It ain’t just dippin’ metal in some hot stuff and callin’ it a day. It’s a process, and if you want it to last, you gotta pay attention to the details. And that includes gettin’ that coating thickness just right, not too thin, not too thick, but just right, like Goldilocks and her porridge, you know?

Thickness of galvanized coating, it ain’t somethin’ most folks think about, but it’s important if you want your metal stuff to last. Whether it’s a fence post, a gate, or part of your barn roof, that coating is what’s keepin’ the rust away. And a good, thick coat means fewer worries and less work down the road, and that’s somethin’ everyone can appreciate.

Tags: [Galvanized Coating, Coating Thickness, Metal Protection, Zinc Coating, Steel Durability, Corrosion Resistance, Hot-Dip Galvanizing, Grit Blasting, Weld Quality, Coating Weight]