Well, howdy there! Let’s talk a bit about heat treatin’ that cold rolled steel, ya hear? It ain’t as simple as throwin’ it in the fire, no sirree. There’s a whole heap of stuff to know.

First off, why do we even bother heat treatin’ this stuff? I tell ya, it’s all about makin’ it better. Stronger, ya know? Like them fellas at the gym pumpin’ iron, we’re pumpin’ heat into that steel. Makes it harder, tougher, and able to take a lickin’ and keep on tickin’. This heat treatment helps to improve the strength and hardness of the steel. It can also make it less brittle, so it don’t snap on ya like a dry twig.

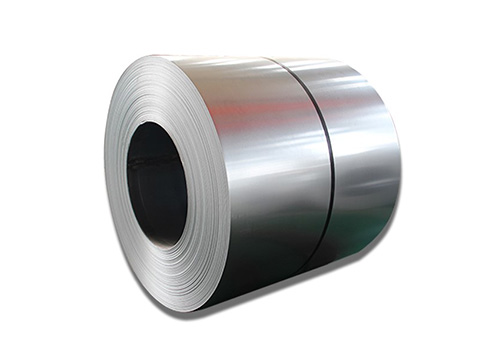

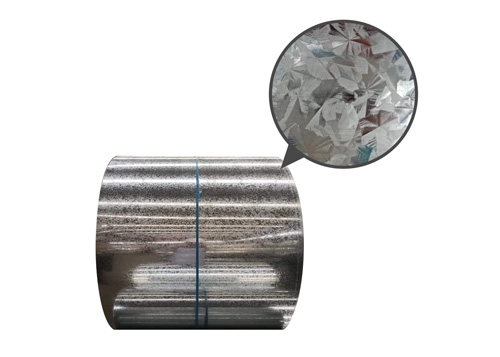

Now, cold rolled steel, that’s the fancy stuff. They don’t make it all hot and bothered like the other kind. Nope, they do it at room temperature. Unlike hot-rolled steel, cold-rolled steel is processed at room temperature. Makes it smoother, prettier, and more precise, like cuttin’ a quilt with a good pair of scissors instead of a rusty ol’ knife. But even that pretty stuff needs a little help sometimes. It’s strong, mind you, stronger than the hot rolled kind. They say it’s got a tensile strength of somethin’ like 85,000 psi, whatever that means. Sounds mighty tough to me. Cold rolled steel is stronger and harder than hot rolled steel.

So, what happens when we heat treat it? Well, it’s like bakin’ a cake, but with a lot more fire and a whole lot less sugar. We heat it up, but not so much that it melts. Just enough to change things inside, ya know? It’s like when you get mad and your face turns red – things are changin’ inside, even if you look the same on the outside. Heat treatment involves heating the metal without melting it. We can make it harder, so it don’t scratch easy. We can make it stronger, so it don’t bend out of shape. And we can even make it less brittle, so it don’t shatter when you drop it. That’s important, ’cause nobody wants a tool that breaks the first time you use it.

- Hardness improvement

- Strength enhancement

- Brittleness reduction

They say there’s things called “metallurgical processes” and “recovery” and “recrystallization”. Sounds like a bunch of fancy words to me. But what it boils down to is this: we’re fixin’ the inside of the steel, gettin’ rid of all the stress and tension that builds up when they roll it cold. Think of it like kneadin’ dough – gotta get all them lumps out before you can bake a good loaf of bread. Heat treatment can remove the internal stresses caused by cold rolling. If we don’t do it right, though, we can mess things up. The steel might get too hard, or too soft, or just plain weird. So, you gotta know what you’re doin’. It ain’t like throwin’ a steak on the grill, ya hear?

And let me tell ya, heat treatin’ ain’t just one thing. There’s a whole bunch of different ways to do it, dependin’ on what you want the steel to do. It’s like cookin’ – you can fry it, bake it, boil it, or even grill it, and each way gives you somethin’ different. Same with steel. Some ways make it harder, some make it tougher, some make it more resistant to rust. It all depends on what you need that steel for.

Cold rolled steel is already pretty darn strong to begin with, ya see? They start with hot rolled steel, then they treat it at room temperature and roll it some more. Cold rolled steel is hot rolled steel that has been further processed at room temperature. So, it’s like givin’ it a double dose of tough. But sometimes, even that ain’t enough. That’s when the heat treatin’ comes in.

And another thing, hot rolled steel, it’s more flexible, ya know? Easier to bend and shape. But cold rolled steel, not so much. It’s mostly flat, square, or round. Hot rolled steel has greater moldability, while cold rolled steel is limited to shapes like flat, square and round. You can’t make all sorts of fancy shapes with it, but what it does, it does good. It’s strong and reliable, and that’s what matters most, ain’t it?

So, there you have it. A little bit about heat treatin’ cold rolled steel. It ain’t rocket science, but it ain’t exactly child’s play either. It takes skill, knowledge, and a whole lotta patience. But when you do it right, you end up with a piece of steel that’s strong, tough, and ready to do whatever you need it to do. And that, my friends, is a good thing.

Tags: [heat treating, cold rolled steel, steel properties, metalworking, metallurgy, hardening, tempering, annealing, stress relief, mechanical properties]